Explore the 3 Channel Production Counter Capabilities

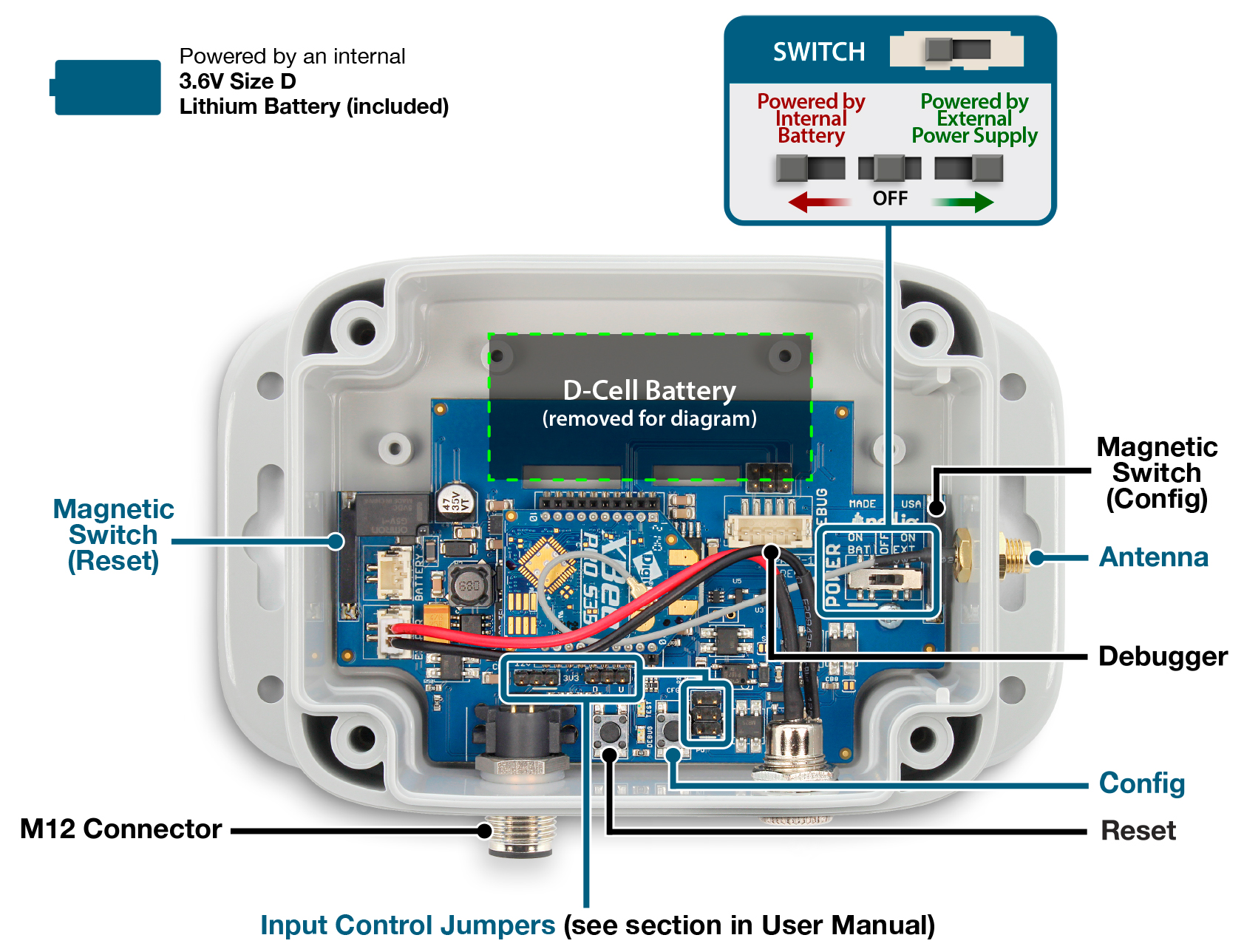

Device Overview

The 3 Channel Production Counter is a device specifically designed to track production counts and machine uptime events in industrial settings. It is a flexible device that can be configured to observe one or more events via different input types – break beam sensor, photo eye sensor, reflector sensor, dry contact closure, and wet contact closure.

It has long range wireless capabilities utilizing robust Mesh networking protocols with high level of security and network reliability. It is compact, durable, and powered by long-lasting batteries.

Features

- Industrial Grade Production Count Monitoring

- Measure Production Uptime

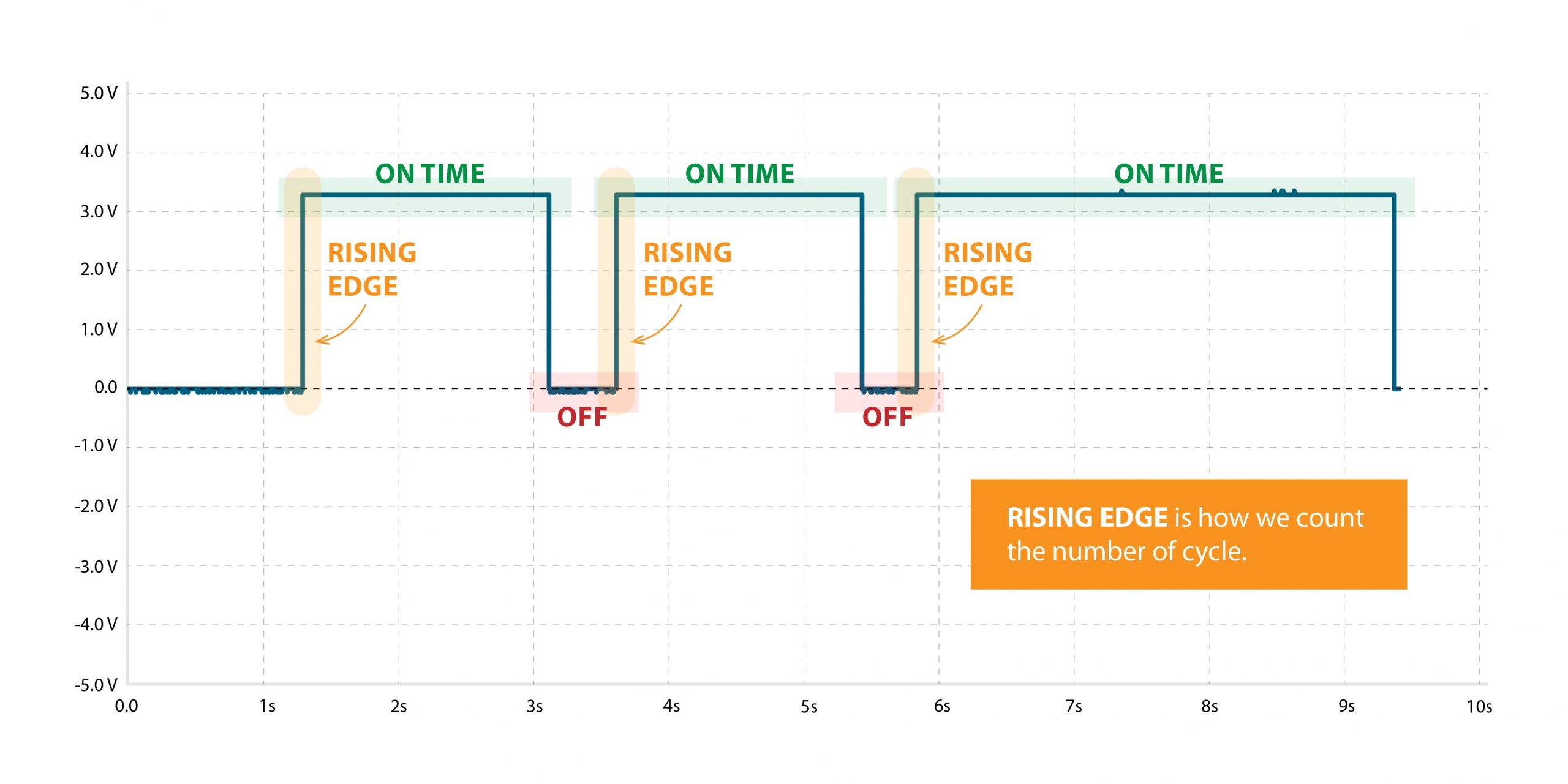

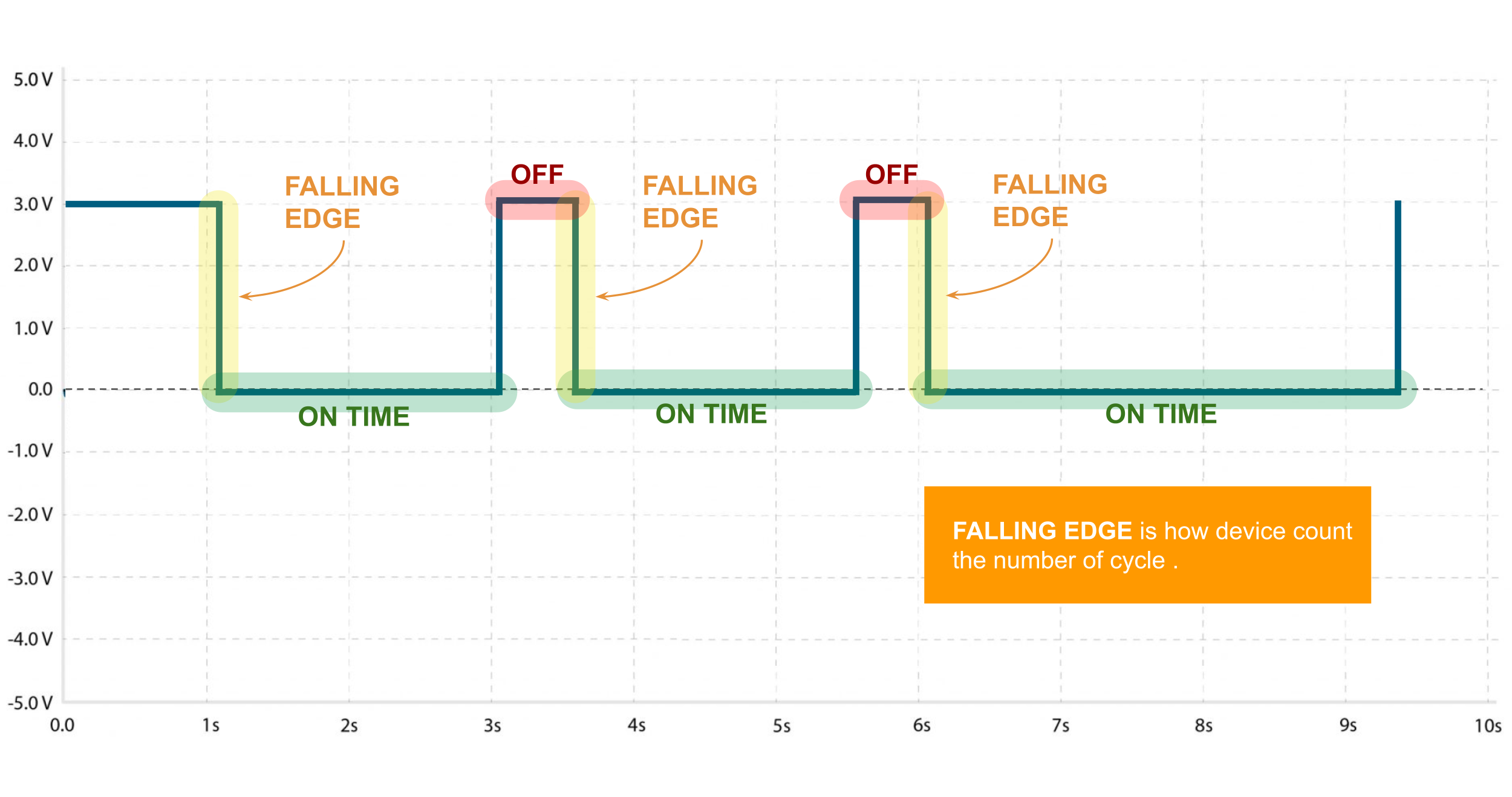

- Measure Number of Cycles

- Dry Contact Closure Input

- Wet Contact Closure Input

- Beam Break and Photo Eye Sensor Input-Based Event Detection

- Encrypted Communication with 2 Mile Wireless Range

- Operating Temperature Range -40 to +85 °C

- Humidity Range 0–90%

- Wall-Mounted or Magnet Mounted IP65 Rated Enclosure

- For Indoor and Outdoor Use

- Many Gateway and Modem Options Available

Status LED

The Status LED is used to indicate errors or other sensor diagnostics.

LED blinks once – Message was sent successfully and no error in last sensor read as well in data transmission.

LED blinks twice and then one more time – Message was sent successfully but there was an error in last sensor read.

LED blinks thrice – MCU is having issue communicating with the radio module.

Sensor Specifications

| Specifications | Minimum | Nominal | Maximum | Notes |

|---|---|---|---|---|

| Width | 3.54" | |||

| Length | 4.52" | |||

| Height | 2.16" | |||

| Enclosure Rating | IP65, NEMA 1,2,4,4X,12,13, UL-508 | |||

| Temperature Rating | -40° C | 23° C | 85° C | Component Rating |

| Tested Temperature | 0° C | 23° C | 40° C | As Tested by NCD Staff |

| Probe Operating Temperature | -40° C | 23° C | 85° C | As Tested by NCD Staff |

| Inputs | Digital, Acceleration, Magnetic, Current | |||

| Opto-input Voltage | 3.3 V | 24V | ||

| Reporting interval | 5 seconds | 600 seconds | 16777215 seconds | How often data is transmitted wirelessly |

| Range of counter values | 1 | 4294967295 | The maximum number of events the sensor can count to | |

| CT Current | 1.5% FS | FS | Minimum current read by the CT. CT range 100 to 1000Amp |

Printed Circuit Board Specifications

| Parameter | Minimum | Nominal | Maximum | Notes |

|---|---|---|---|---|

| Trace Width | 0.007 inch | 0.012 inch | 0.25 inch | Trace Width depends on the Trace Type |

| Layer Count | 2L - Rigid | Top and Bottom Layer | ||

| Material Type | FR-4 TG170 | FR-4 TG170 | FR-4 TG180 | |

| Surface Finish | ENIG 2u" | |||

| IPC Standard | IPC CLASS 2 | |||

| Finished Copper Foil | 1.0/1.0 OZ | |||

| Finished Thickness | 0.062 inc | |||

| Fine line <4.0/4.0mil | No | |||

| Blind & Burried Vias | No | |||

| Non-Conductive Resin | No | |||

| Conductive Resin | No |

Mechanical Drawing

RF Module Specifications

| Parameter | 868MHz | 900MHz | 2.4GHz |

|---|---|---|---|

| Frequency Band | 863 MHz to 870 MHz | 902 to 928 MHz | ISM 2.4 GHz |

| Transmitter Power | Up to 13 dBm ERP | Up to 24 dBm | Up to 8 dBm |

| Receiver Sensitivity | -106 dBm at 80 Kbps | -101 dBm at 200 Kbps | -103 dBm at 250 Kbps |

| Range (dense urban) | ~1000ft | ~1000ft | ~300ft |

| Range (line of sight) | ~2 miles | ~2 miles | ~1 mile |

| Data Rate | 80 Kbps | 200 Kbps | 250 Kbps |

| Networking Protocol | Digi XBee® DigiMesh® | Digi XBee® DigiMesh® | Digi XBee® DigiMesh® |

| Encryption | 128-bit AES | 128-bit AES | 128-bit |

| Reliable Packet Delivery | Retries/acknowledgements | Retries/acknowledgements | Retries/acknowledgements |

| IDs | PAN ID and addresses, cluster IDs and endpoints (optional) | PAN ID and addresses, cluster IDs and endpoints (optional) | PAN ID and addresses, cluster IDs and endpoints (optional) |

| Certification | CE/RED, ROHS Compliant | FCC (America), IC (Canada), C-Tick (Australia), Anatel (Brazil), IDA (Singapore) | FCC (America), IC (Canada), RCM (Australia), Anatel (Brazil), Teleck MIC (Japan), KCC (South Korea) |

Probes Specifications

Digital Inputs

The Industrial Digital Input and Sensor Reader is a compact and robust device tailored to interpret signals from various digital inputs and sensors prevalent in industrial settings, including brake beam sensors, photo reflectors, photo eye sensors, and on/off signals. It can also work with counter with a digital pulse outputs to easily integrate with existing equipment in production lines or plants for example.

With high accuracy and reliability, it offers real-time data acquisition and monitoring, seamlessly integrating into existing industrial automation systems. Its user-friendly interface and flexible configuration options ensure easy setup and compatibility with diverse applications, enhancing operational efficiency, equipment reliability, and production optimization. Ideal for conveyor systems, packaging machinery, and robotic systems, it empowers industrial operators with streamlined data interpretation and control capabilities, minimizing downtime and maximizing productivity.

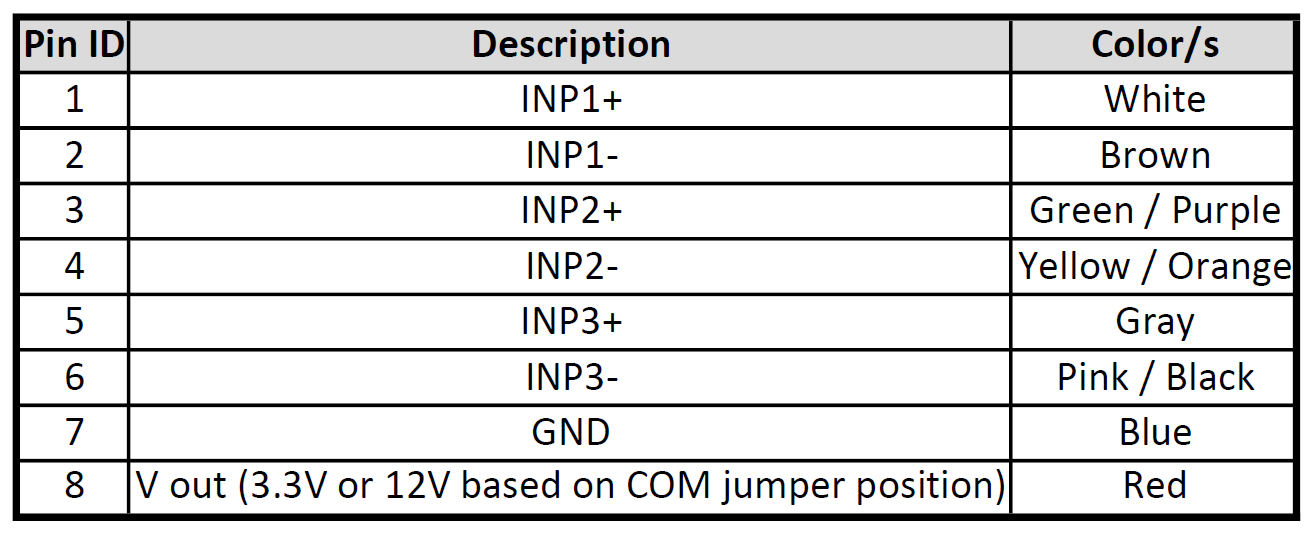

Probe Configuration and Wiring

Power Requirements and Expected Battery Life

Power Requirements

- This device is Powered by a single D-cell (LR20) battery

While changing the batteries:

- Turn off the sensor

- Only use a new D-cell battery (obtain one from NCD, as it has a built in supercapacitor, this is not a regular battery).

- Make sure to align the connector in the proper orientation (this will assure you match the polarity)

- The battery should not be replaced in fire-risky areas

- Do NOT install a rechargeable battery

Expected Battery Life

| Specifications | Minimum | Nominal | Maximum | Notes |

|---|---|---|---|---|

| Batteries size | 16000mAh | This device has a single D-Cell (LR20) battery | ||

| Battery Life 1 TPD | 10 Years | TPD Transmissions per Day | ||

| Battery Life 12 TPD | 8 Years | TPD Transmissions per Day | ||

| Battery Life 24 TPD | 5 Year | TPD Transmissions per Day | ||

| Battery Life 96 TPD | 3 Year | TPD Transmissions per Day |

Head to the NCD store if you want to purchase the 3 Channel Production Counter.

If you already have the device and would like more information into its basic and advanced operations check out the Quick Start Guide and User Manual.