Challenge

Breaking the Cycle of Reactive Maintenance

A leading manufacturer was struggling to maintain its fleet of rotating assets, over 60% of which were legacy machines. Despite a routine of monthly preventive maintenance (PMs), the team faced constant challenges that hampered efficiency and inflated costs.

Despite spending over $72,000 USD annually in preventive maintenance (PM), the program delivered only 75% availability, far below expectations for such critical rotating assets.

The core issues were clear:

- Unexpected Breakdowns: Critical equipment failed without warning, causing costly production halts.

- High Reactive Costs: Emergency repairs and unplanned downtime were a constant drain on resources.

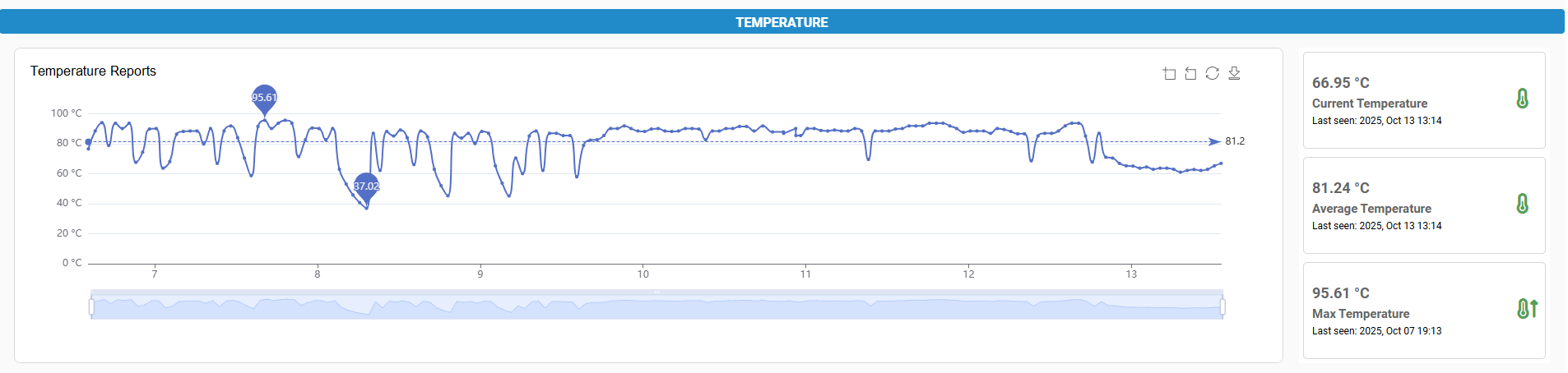

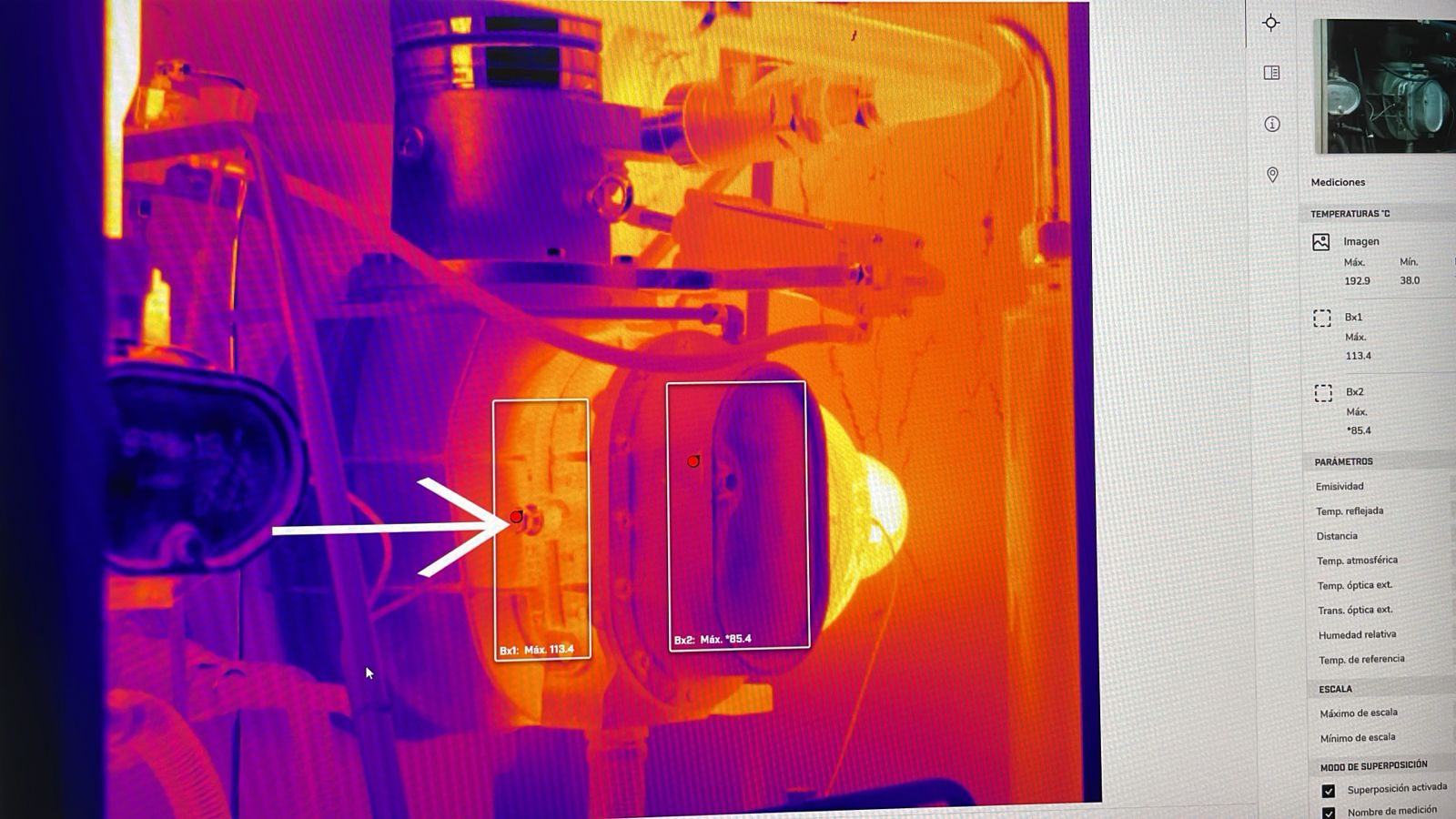

- Missed Warning Signs: Manual, periodic inspections lacked the precision to catch early indicators of wear and tear like subtle changes in vibration or temperature.

- Inefficient Inspections: Time-consuming manual checks failed to provide the real-time data needed for proactive decision-making.

An initial attempt to install a wired monitoring system proved too complex and costly to deliver a clear ROI. The manufacturer urgently required a cost-effective, easy-to-deploy solution that could provide real-time insight into machine health and predict failures before they occurred. Subsequent trials with other wireless technology providers fell short due to high costs, poor performance, and inability to operate reliably in the demanding high-temperature environment.

Solution

A Unified AIoT Platform for Actionable Insights

Webee delivered a comprehensive solution combining easy-to-install IIoT hardware from NCD with its powerful, no-code AIoT platform. The goal was to provide real-time visibility, automate anomaly detection, and empower the client’s team with prescriptive maintenance tasks, all while ensuring a rapid and justifiable ROI.

The Approach in Action

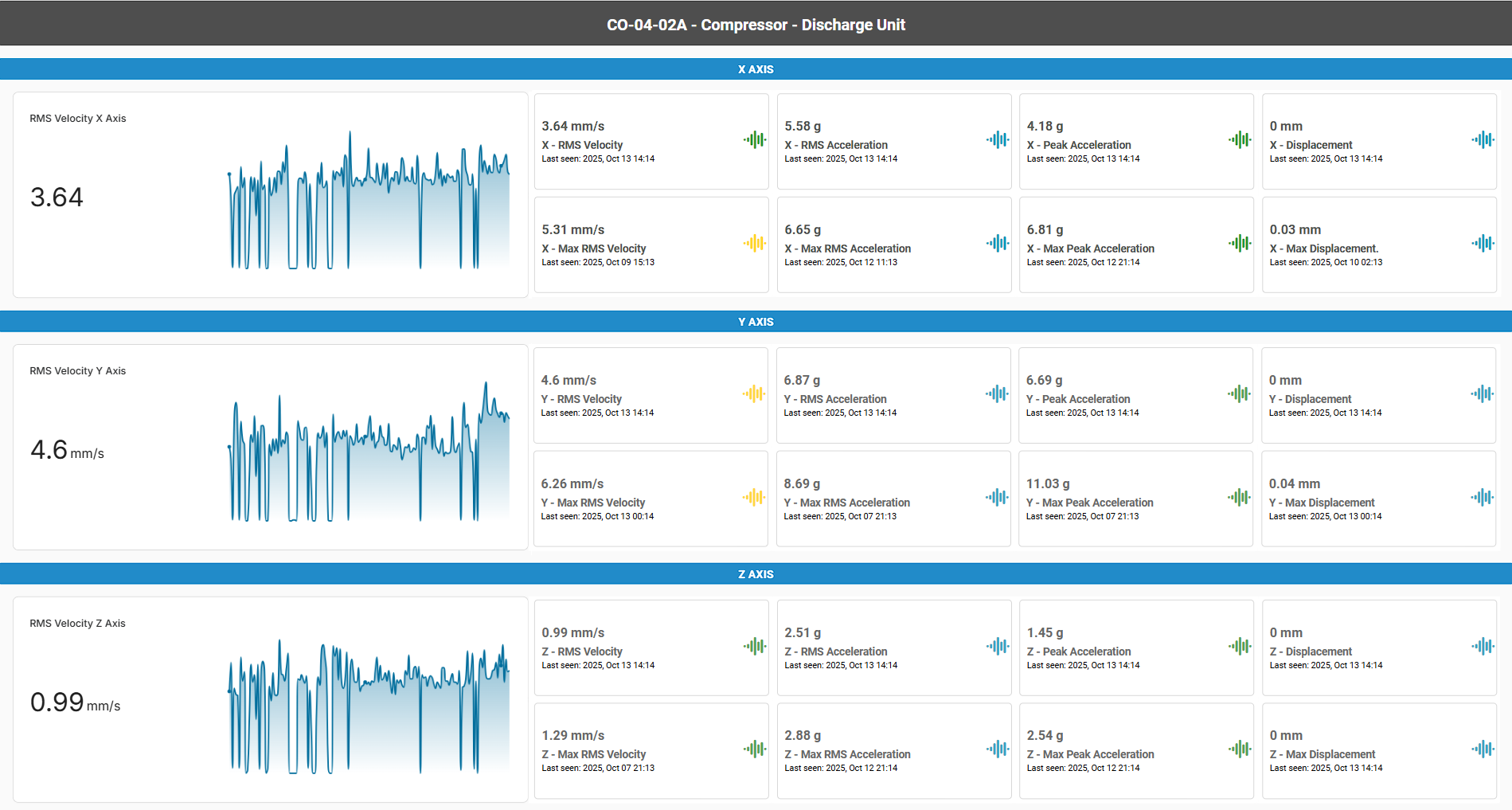

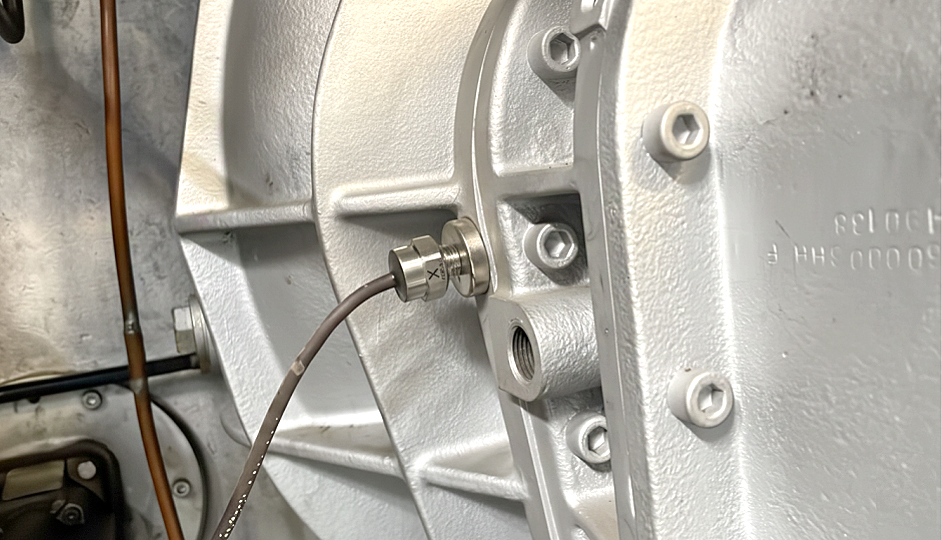

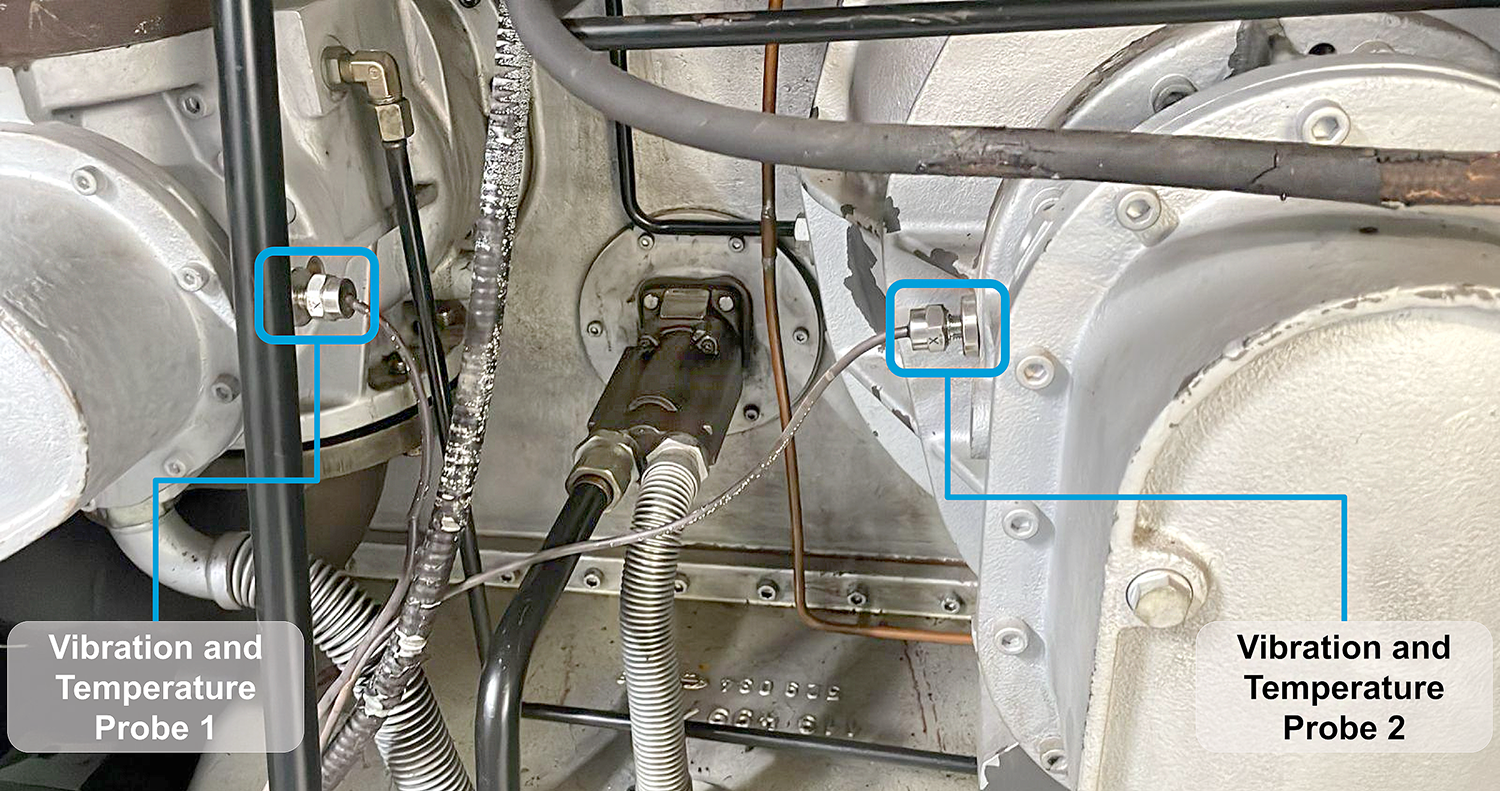

Rapid Deployment: The NCD Two-Channel Vibration Sensors Gen 4 were installed on critical rotating equipment using a simple “plug-and-play” method. These battery-powered sensors immediately began capturing key metrics, including:

- 3-axis Vibration

- Frequency

- RPMs

- Surface temperature.

Solution Architecture

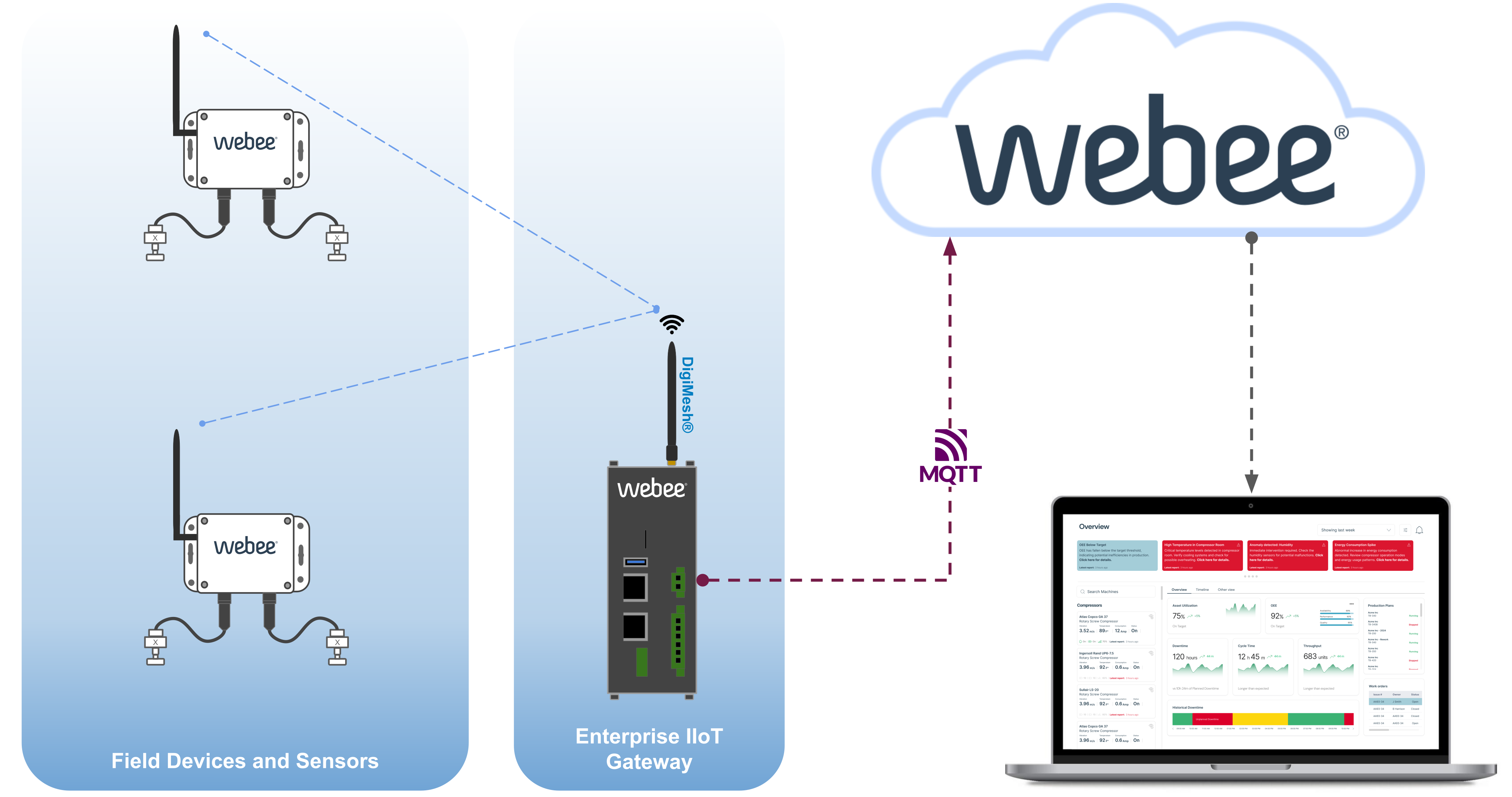

The NCD Sensors wirelessly streamed data to an Enterprise IIoT Gateway using the DigiMesh protocol. The Gateway then sent the sensor data directly to the Webee platform.

Once the data reached the Webee platform, the client’s team was able to use the intuitive, no-code interface to easily pair each sensor with its corresponding asset, bringing live data visualizations online within minutes.

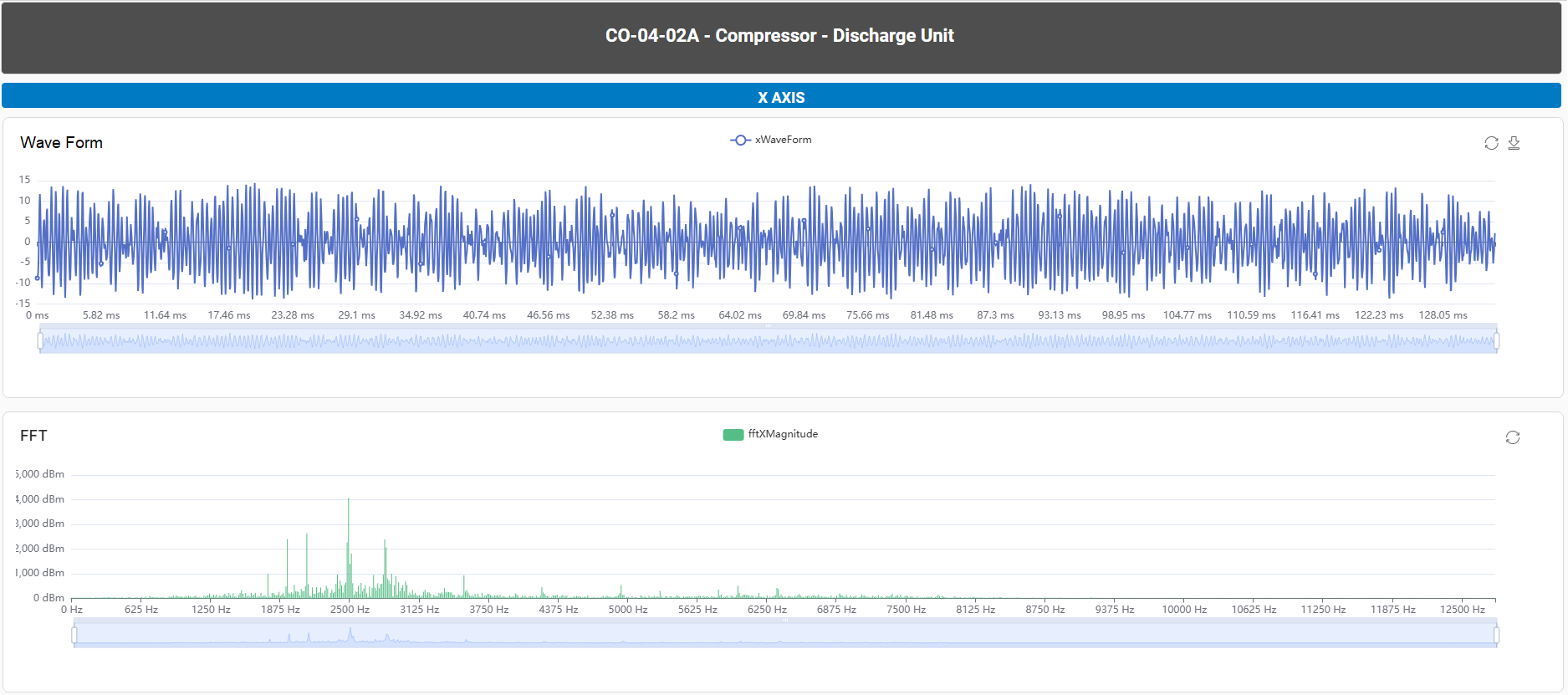

- AI-Powered Anomaly Detection: The platform’s patented AI algorithms immediately began analyzing the incoming data stream. It learned the normal operating behavior of each machine, allowing it to automatically detect subtle anomalies—like a minor increase in vibration—that indicated potential issues such as misalignment, imbalance, or bearing wear.

- Prescriptive Alerts & Task Management: Instead of just flagging a problem, the system provided actionable intelligence. When an anomaly was detected, customized alerts were sent via email and SMS to the maintenance team. The platform generated prescriptive work orders, telling the team not only which machine needed attention but also what the likely issue was and when maintenance should be scheduled, enabling timely maintenance actions.

- AI-Powered Asset Intelligence & Root Cause Analysis: The platform not only monitored real-time data but also mapped all assets, devices, and their interconnections in a comprehensive knowledge graph. By understanding relationships between machines, sensors, and historical events, it leveraged KCN-based AI analytics to identify the root causes of anomalies. When a vibration spike or other irregularity occurred, the system could trace it back through the asset network, pinpointing whether the issue stemmed from a specific component, operational condition, or upstream equipment, enabling maintenance teams to act with precision and confidence.

- AI Maintenance Coordinator: Acting as a proactive digital assistant, the AI Maintenance Coordinator automates the entire maintenance workflow, from processing maintenance requests and triaging alerts to scheduling tasks. By interpreting AI-driven insights, historical machine data, and root cause analysis, it guides technicians on what actions to take, when, and on which equipment, executing agentic workflows to optimize maintenance operations across the plant. The coordinator can answer questions like “Which machines require urgent attention?” or “What corrective steps are recommended?” in real time, helping the team make faster, more informed decisions, reduce human error, and ensure critical assets remain operational.

Dashboard

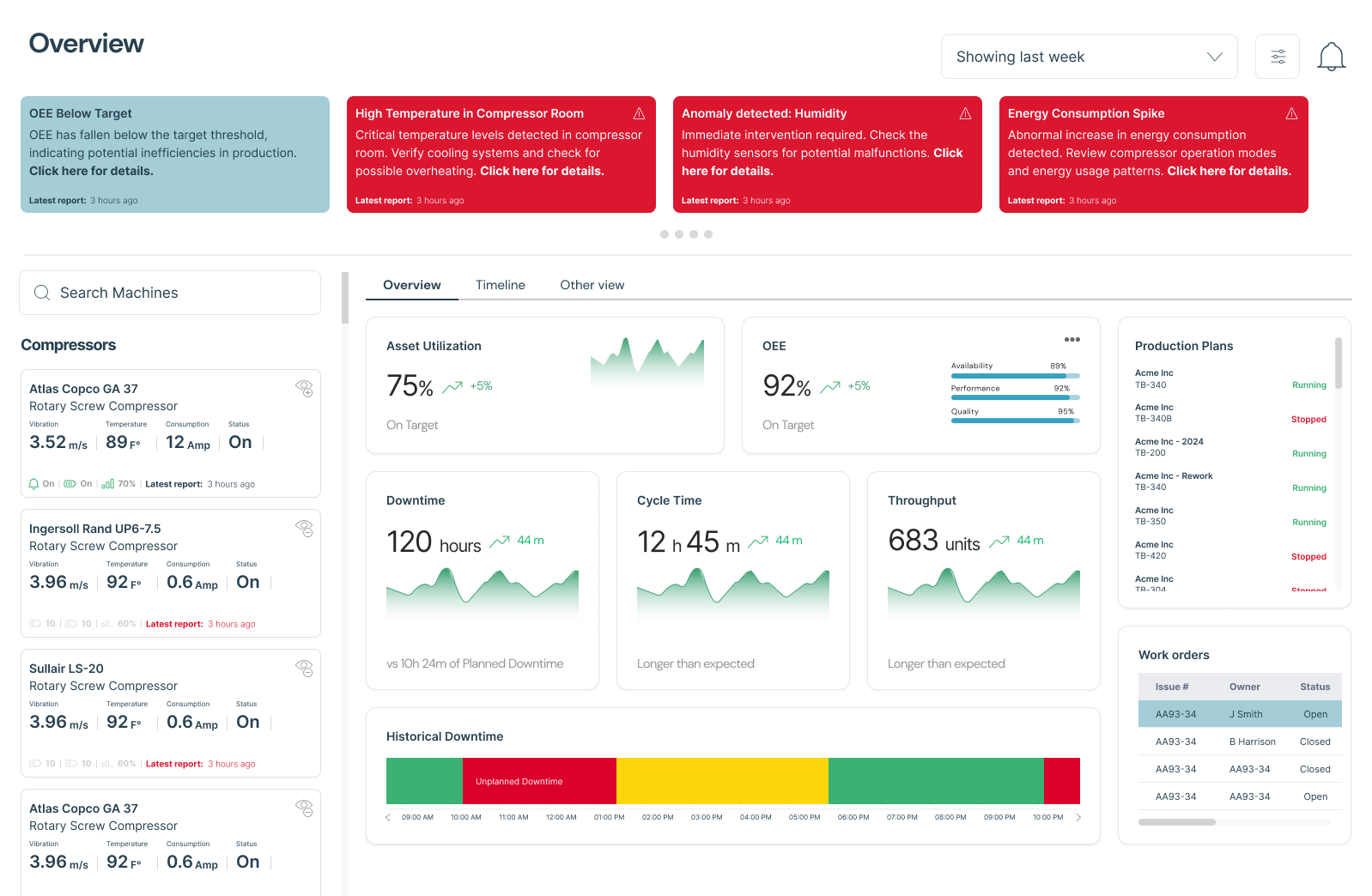

Overview: Machine Health & Performance – 24/7 Real-Time Control

Gain instant visibility into equipment health and production metrics with Webee’s Maintenance Intelligence Software. Monitor performance, detect anomalies, and prioritize actions through wireless, non-intrusive sensors.

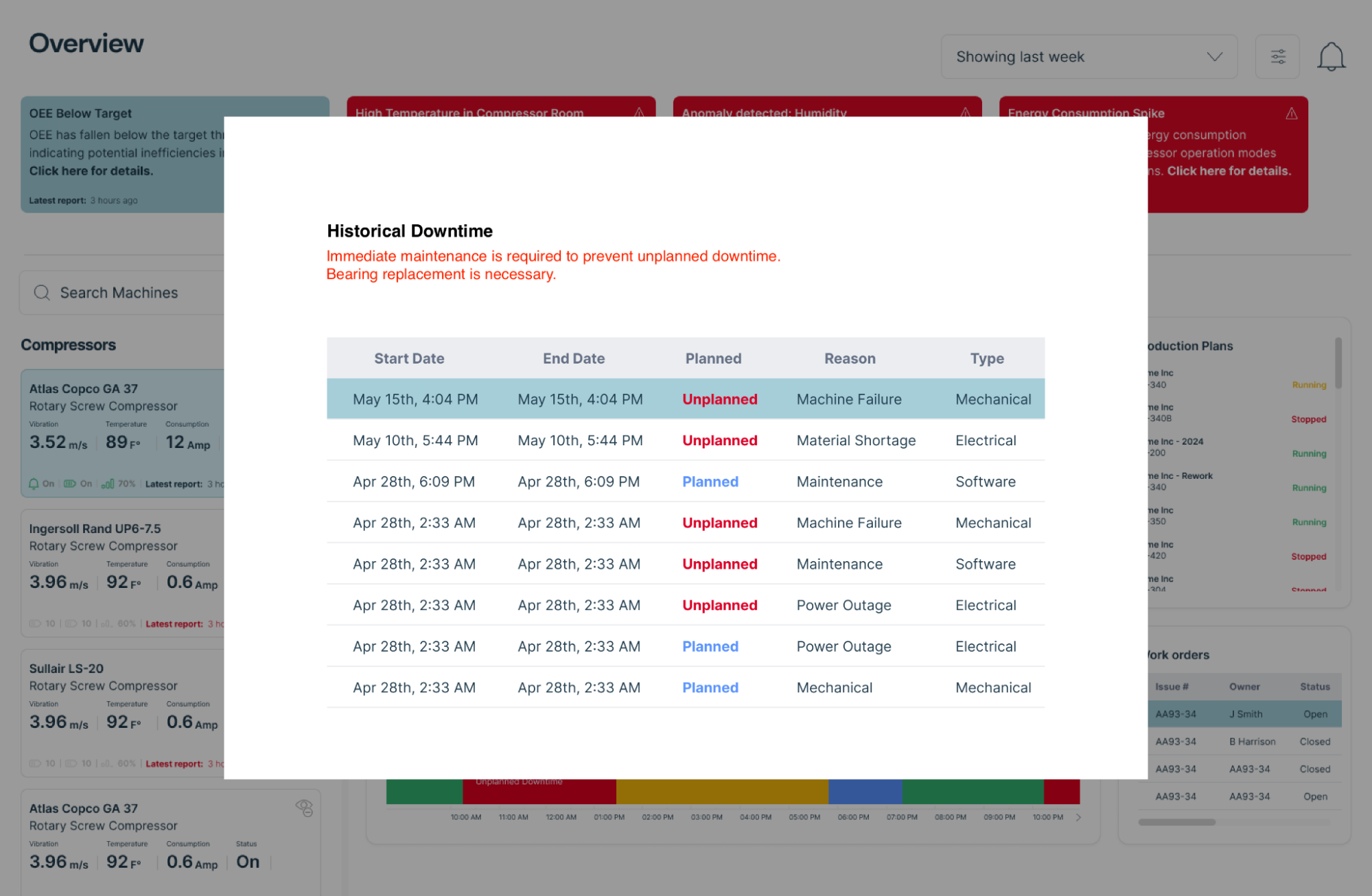

Downtime Analysis: Root Cause Tracking

Historical downtime trends and root cause insights help identify recurring issues, optimize maintenance schedules, and reduce unplanned production stops.

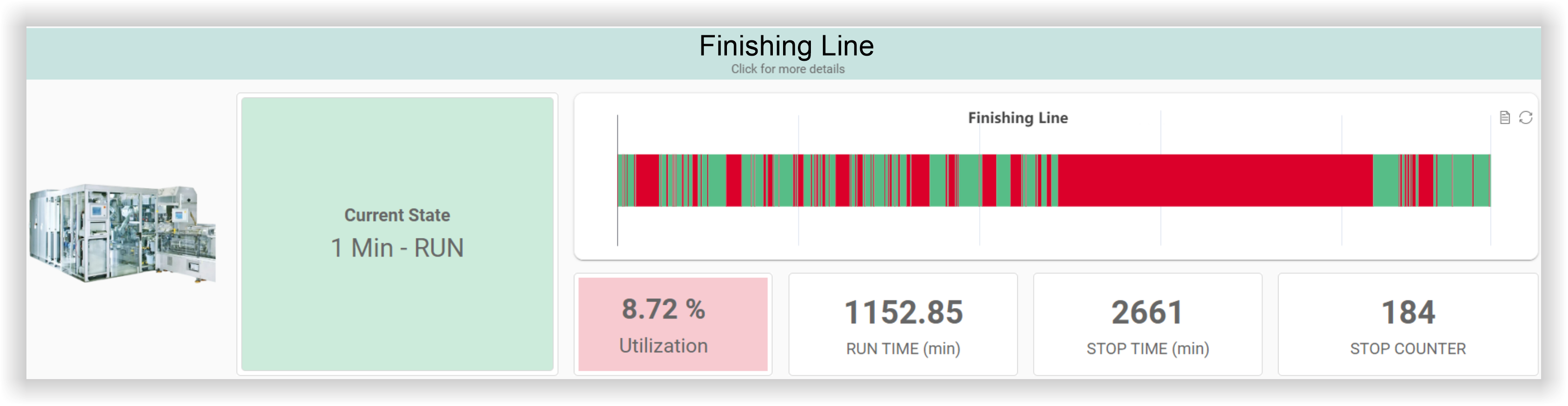

Asset Performance Dashboard

Comprehensive asset performance summary including utilization hours, runtime status, and operational health to support data-driven maintenance decisions.

Impact

A New Standard of Operational Excellence

The transition from a reactive to a predictive maintenance strategy delivered immediate and significant results. By leveraging the combined power of NCD sensors and the Webee platform, the manufacturer transformed its operations.

Key Outcomes:

Drastic Availability Improvement: Availability jumped from 75% to 87%.

Drastic OEE Improvement: Overall Equipment Effectiveness jumped from 69% to 75%.

Proactive Failure Prevention: Real-time monitoring of all the critical assets allowed the team to detect issues early and prevent unexpected downtime.

- Data-Driven Decisions: The platform analyzed over 3.7 million data samples to generate more than 400 actionable insights, shifting the focus from scheduled check-ups to condition-based maintenance.

- Optimized Resource Allocation: Unnecessary PMs were eliminated, freeing up the maintenance team to focus on proactive tasks that added genuine value.

The implementation resulted in a remarkable improvement in equipment availability, which increased from 75% to 87%. Indirectly, this also boosted the production Overall Equipment Effectiveness (OEE) from 69% to 75%, significantly reducing downtime-related losses and manual maintenance costs.

Fast-Facts:

Save 40% repairing time

Improve 12% machine availability

Reduce 10% the Total maintenance cost

$350,000 saved from avoided unplanned production downtime during the first year.

Whats Next?

Scaling Success Across the Enterprise

With a proven model for success, the client is now expanding the Webee and NCD solution across its wider operations. The maintenance team spends less time reacting to emergencies and more time strategically preventing them.

By turning machine data into a predictable asset, they are not just saving money on repairs—they are protecting uptime, maximizing productivity, and setting a new, more reliable standard for industrial maintenance.

This marks a transformative step toward fully predictive, data-driven maintenance across all operations, powered by IoT and agentic AI workflows that autonomously prioritize and execute maintenance actions.

Focus Product

The Gen4 Wireless Vibration & Temperature Sensor is a cutting-edge solution designed for full-spectrum machine health monitoring in the toughest industrial environments. By fusing triaxial MEMS accelerometers with a precision surface temperature element this sensor captures a holistic signature of your machine’s condition.

The Enterprise IIoT Gateway is designed to make deployment of your next IIoT installation simple, effective, and customizable. With built-in Node-Red capabilities for no-code integration into new and existing cloud/SCADA systems, web based security and access management, SSH access to the Debian OS for full customization, as well as VPN and Remote Management options this Edge Computer will make your next deployment seamless.

About

Webee

Webee is a web-based Industrial IoT (IIoT) and Artificial Intelligence (AI) platform that empowers industrial companies to connect assets, monitor performance, and make smarter, data-driven decisions in real time. Through a no-code environment, enables seamless integration of wireless sensors, devices, and systems such as PLCs, SCADA, and ERP. Its AI engine and intelligent AI Agents—virtual teammates that learn and act autonomously—transform raw data into predictive insights that improve efficiency, prevent unplanned downtime, and enhance productivity.

Focused on scalability, sustainability, and operational excellence, helps enterprises accelerate digital transformation and achieve measurable impact across their operations.

NCD.io

IoT Hardware Design and Development Company specializing in Wireless IoT sensors. It offers a wide range of plug-and-play devices for monitoring temperature, humidity, pressure, energy, acceleration, gas, and industrial I/O. Our devices allow control over pumps, valves, motors, relays, and more.

ncd.io has over one thousand products in its portfolio and serves over 3000 clients a year. We pride ourselves on our excellent Engineering services and top-of-the-line equipment to produce top-of-the-line products.

All products are manufactured in the USA. Since 1995, NCD.io has been providing custom IoT hardware and firmware solutions.

Connect

Seeking next-generation IIoT solutions and support? Here are some next steps:

- Cuntact us to talk to a NCD Technicial Support.

- Visit our Blog Entries to learn about emerging trends.

- Shop for solutions from NCD and our partners.