The Client, a leading North American building materials company. It provides building solutions for infrastructure, residential, and commercial projects across the North America and South America. As one of the largest building materials firms in the US, it holds top positions in cement, aggregates, and commercial roofing.

Challenge

The Limitations of Manual Reliability

The client, a large-scale manufacturing facility, already possessed a dedicated reliability team. However, their maintenance strategy relied heavily on “vibration routes”—manual inspections where technicians would walk the plant to take readings.

While the team was skilled, the process had inherent flaws:

- Infrequent Data: Machines were only checked “every so many weeks,” creating massive blind spots where failures could develop unnoticed.

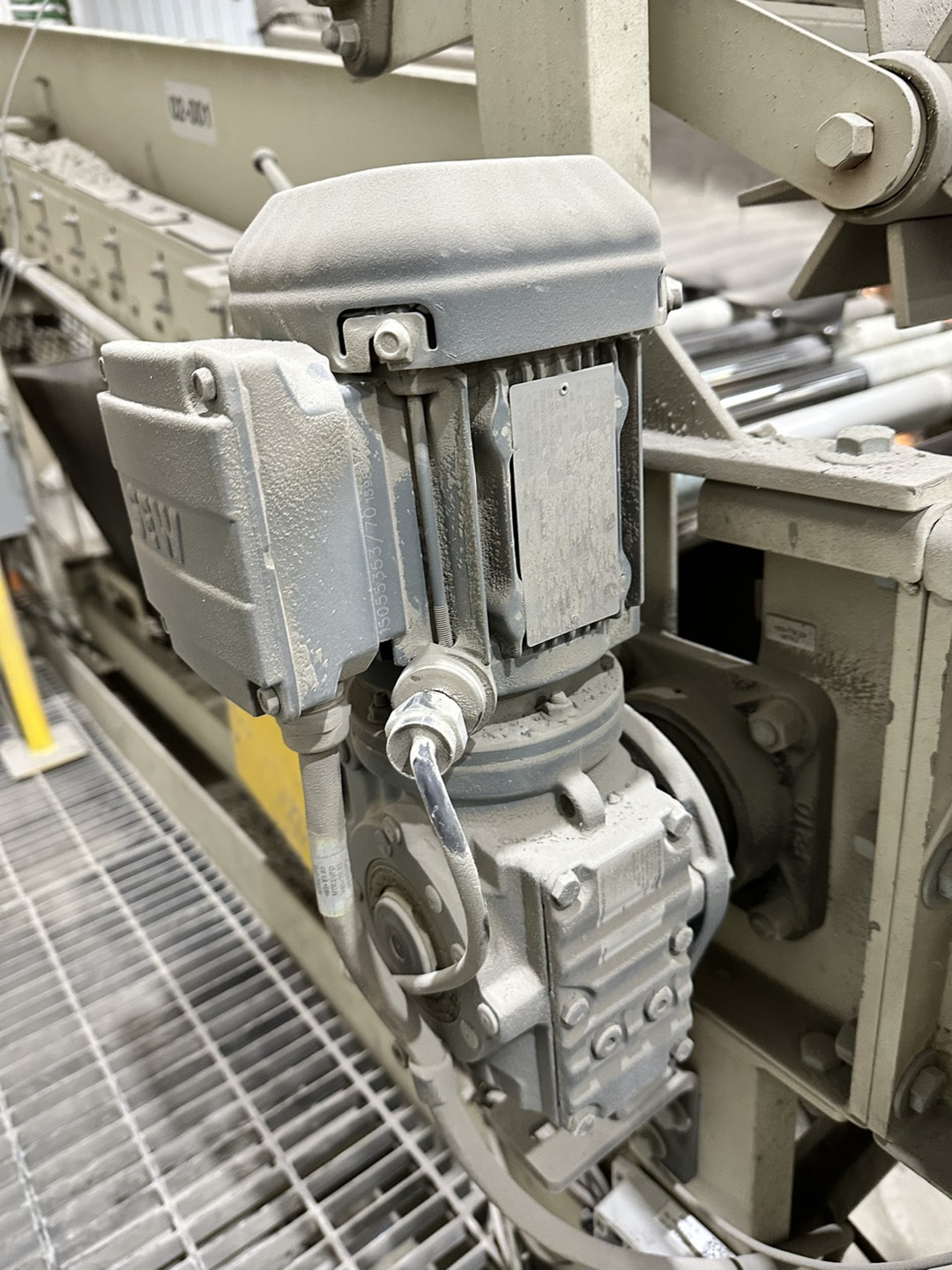

- Inaccessibility: Many critical assets, such as bucket elevators, were located in hard-to-reach areas where running power or wired sensors was cost-prohibitive or impossible.

- Reactive vs. Proactive: Without continuous data, the team often had to “chase issues when they happened” rather than predicting them.

The client realized that to move from Preventative to Predictive maintenance, they needed a wireless solution to fill the gaps between manual inspections.

"We wanted to have something that's a little bit more automated... so that we can get data on stuff when we're not looking at it."

Electrical Engineer

Solution

The client evaluated 10 to 12 different IoT companies before selecting NCD. Most competitors were rejected for three specific reasons:

- Data Hostage: Competitors insisted on cloud-based systems where the vendor owned the data, potentially selling it or locking the client out.

- Recurring Costs: High monthly or yearly subscription fees (SaaS models) effectively punished the client for scaling up.

- Proprietary Hardware: Many systems required expensive, proprietary batteries that were difficult to source.

Why NCD?

NCD stood out as the “flexible option” that aligned with the client’s strict requirements:

- Data Ownership: The client retains 100% control of their data with no third-party lock-in.

- No Monthly Fees: One-time hardware purchase with no recurring contracts.

- Flexibility: The ability to program the Gateway using Node-RED allowed the client to structure data exactly how they wanted.

- Ease of Maintenance: NCD sensors utilize standard AA Lithium batteries available at retail stores, eliminating supply chain headaches.

"That was another thing that prevented us from doing these other companies... they did not want to allow us to own our data. We actually had to own the data coming out of the sensors."

Electrical Engineer

The Implementation

Overcoming Harsh Conditions & IT Firewalls

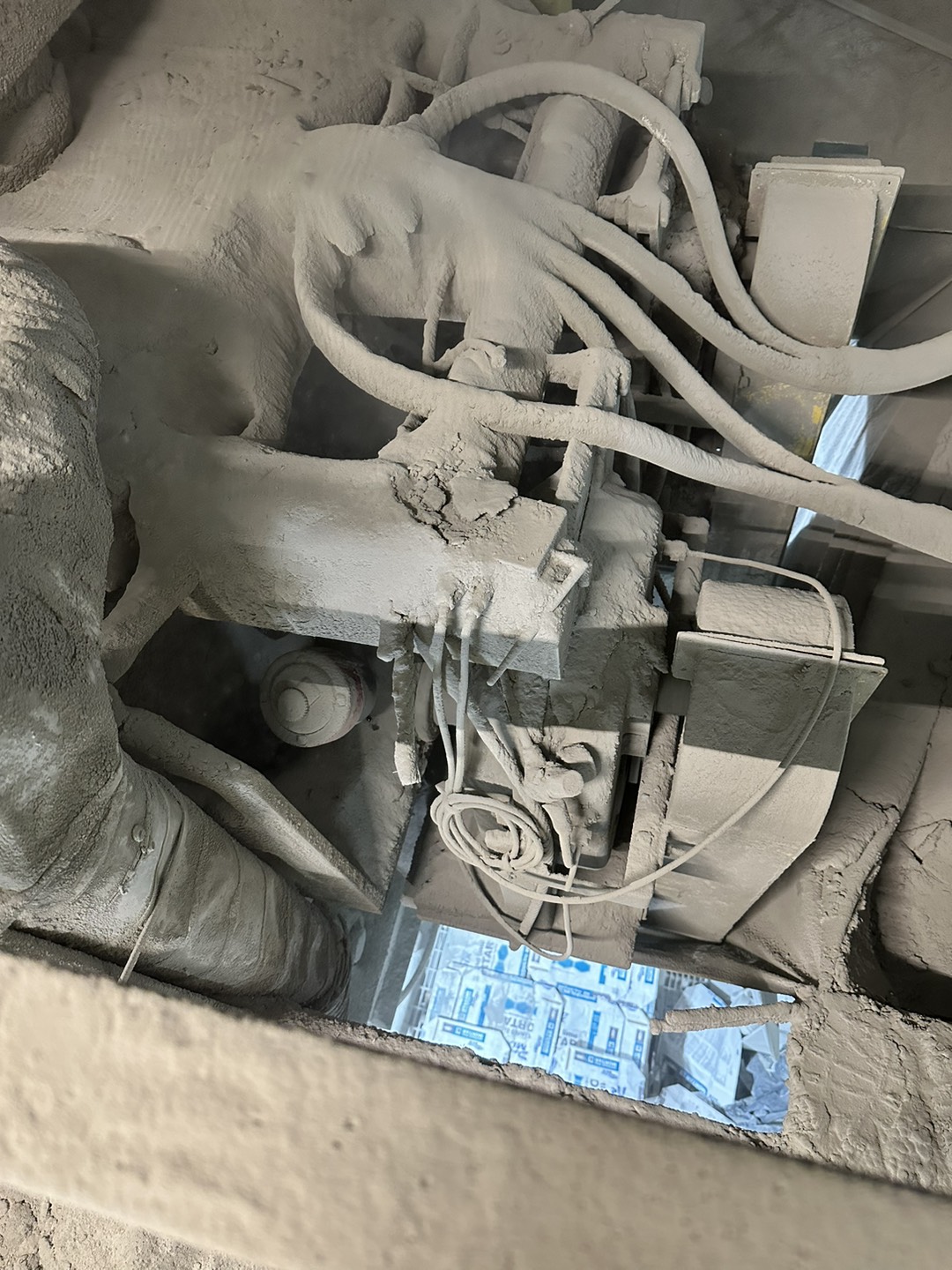

The installation environment was “harsh,” characterized by heavy dust and fine powdery material. Additionally, the wireless signal had to penetrate electrical rooms built of cinder blocks and pass through dense metal infrastructure.

Performance

Despite the interference, the NCD sensors maintained excellent range and signal integrity. The hardware proved durable against the dust and industrial contaminants.

IT Integration

The biggest hurdle was not the hardware, but the facility’s strict IT infrastructure. The client does not allow cellular connections for security reasons, requiring a hardwired Ethernet connection for the Gateway. Once the firewall rules were adjusted to allow data flow, the system was live and streaming data within days.

The Impact

Visibility and Peace of Mind

While the installation is in the early stages, the facility has already noted significant operational shifts:

- 24/7 Visibility: The reliability team now has a constant “pulse” on the plant. They are no longer waiting for a route check to see a temperature spike or vibration anomaly.

- Infrastructure-Proof: The system successfully bypassed the need for expensive conduit runs to difficult locations.

- Rapid ROI: By avoiding monthly fees and utilizing cost-effective hardware, the client estimates the system will pay for itself within 6 months to 1 year, purely based on equipment protection and avoided subscription costs.

"It definitely gives us comfort when we go to bed at night... knowing trending is good. We can know what's going on really at any part of the plant whenever we want."

Electrical Engineer

Fast Facts

| | | | | | | | | | | | | | | | |

The Problem: Reliance on manual inspections left critical, hard-to-reach assets unmonitored between rounds.

The solution: NCD Enterprise Wireless IoT Sensors & Gateways integrated via Node-RED.

Key Differentiator: 100% Data Ownership with Zero Monthly Fees.

ROI: Estimated Payback Period: 6–12 Months.

Outcome: 24/7 visibility into asset health, elimination of hazardous manual checks, and scalable predictive maintenance.

Whats Next?

AI and Expansion

With the foundational data layer now established, the client is moving to the next phase of their digital transformation:

- AI Modeling: Using the sensor data to build “normal running condition” models and using AI to trigger alerts when deviations occur.

- Expansion: Rolling out NCD sensors to other plants, specifically targeting sites with the technical expertise to leverage the open Node-RED architecture.

- New Asset Classes: expanding monitoring to critical bucket elevators and other assets that were previously “un-monitorable.”

Connect

Seeking next-generation IIoT solutions and support? Here are some next steps:

- Contact us to talk to a NCD Technicial Support.

- Visit our Blog Entries to learn about emerging trends.

- Shop for solutions from NCD and our partners.

Share