Device Overview

Primarily utilized for monitoring structural displacements, the C1D2 Industrial IoT Wireless Structural Monitoring Sensor detects movements and shifts at various structural points. Ideal for installation between footings and walls or alongside steel supports, this sensor reports any alterations in distance due to its spring-loaded cable mechanism. It is perfect for applications such as positional control, beam testing, hydraulic movement detection, and structural shift monitoring. The sensor is secured with two screws, plus an additional screw for the retractable cable, which provides analog position feedback during length changes.

Featuring a single-channel 10-bit ADC, the sensor periodically samples and wirelessly transmits data, entering a low-power sleep mode between transmissions to extend battery life. It can detect positional changes every 7 seconds (configurable), updating the cable length data if displacement varies by more than 10% (configurable). This energy-efficient operation, combined with a broad application spectrum, ensures its versatility. The sensor outputs an analog value from 0 to 1023, indicating full extension or retraction of the displacement cable.

The sensor uses a 50cm retractable wire cable, actively pulling to retract, and provides readings from 0 to 1023 as the cable extends. It should be mounted to track movements between two points, detecting linear shifts without assessing angular changes. Optimal functionality is achieved with the cable partially extended, allowing for precise detection of any length variation. However, it does not measure angular shifts, focusing solely on linear movements.

- Wireless Structural Monitoring Sensor for Structural Monitoring

- Industrial Grade IoT Displacement Sensor

- 10-bit Resolution & Precision ±0.5% FS

- Auto ADC Sample Transmission on Level Change

- Configurable 10% Analog Voltage Change Detection

- 2 Mile Line-of-Sight Range with On-Board Antenna

- Interface with Popular Cloud Platforms:

- Amazon® AWS®, Microsoft® Azure®

- Temboo, MQTT, Losant, Node-Red

- Wireless Mesh Networking using DigiMesh®

- Open Communication Protocol for Easy Software Integration

- Includes Battery Level with Every Transmission

- Validates and Retries Lost Communication Packets

Status LED

The Status LED is used to indicate errors or other sensor diagnostics.

LED blinks once – Message was sent successfully and no error in last sensor read as well in data transmission.

LED blinks twice and then one more time – Message was sent successfully but there was an error in last sensor read.

LED blinks thrice – MCU is having issue communicating with the radio module.

Sensor Specifications

| Specifications | Minimum | Nominal | Maximum | Notes |

|---|---|---|---|---|

| Width | 3.54" | |||

| Length | 4.52" | |||

| Height | 2.16" | |||

| Enclosure Rating | IP65, NEMA 1,2,4,4X,12,13, UL-508 | |||

| Mounting | 1/4 NPT 1/4-28 UNF Magnet Mount | |||

| Temperature Rating | -40° C | 23° C | 85° C | Component Rating |

| Tested Temperature | 0° C | 23° C | 40° C | As Tested by NCD Staff |

Printed Circuit Board Specifications

| Parameter | Minimum | Nominal | Maximum | Notes |

|---|---|---|---|---|

| Trace Width | 0.007 inch | 0.012 inch | 0.25 inch | Trace Width depends on the Trace Type |

| Layer Count | 2L - Rigid | Top and Bottom Layer | ||

| Material Type | FR-4 TG170 | FR-4 TG170 | FR-4 TG180 | |

| Surface Finish | ENIG 2u" | |||

| IPC Standard | IPC CLASS 2 | |||

| Finished Copper Foil | 1.0/1.0 OZ | |||

| Finished Thickness | 0.062 inc | |||

| Fine line <4.0/4.0mil | No | |||

| Blind & Burried Vias | No | |||

| Non-Conductive Resin | No | |||

| Conductive Resin | No |

Mechanical Drawing

RF Module Specifications

| Parameter | 868MHz | 900MHz | 2.4GHz |

|---|---|---|---|

| Frequency Band | 863 MHz to 870 MHz | 902 to 928 MHz | ISM 2.4 GHz |

| Transmitter Power | Up to 13 dBm ERP | Up to 24 dBm | Up to 8 dBm |

| Receiver Sensitivity | -106 dBm at 80 Kbps | -101 dBm at 200 Kbps | -103 dBm at 250 Kbps |

| Range (dense urban) | ~1000ft | ~1000ft | ~300ft |

| Range (line of sight) | ~2 miles | ~2 miles | ~1 mile |

| Data Rate | 80 Kbps | 200 Kbps | 250 Kbps |

| Networking Protocol | Digi XBee® DigiMesh® | Digi XBee® DigiMesh® | Digi XBee® DigiMesh® |

| Encryption | 128-bit AES | 128-bit AES | 128-bit |

| Reliable Packet Delivery | Retries/acknowledgements | Retries/acknowledgements | Retries/acknowledgements |

| IDs | PAN ID and addresses, cluster IDs and endpoints (optional) | PAN ID and addresses, cluster IDs and endpoints (optional) | PAN ID and addresses, cluster IDs and endpoints (optional) |

| Certification | CE/RED, ROHS Compliant | FCC (America), IC (Canada), C-Tick (Australia), Anatel (Brazil), IDA (Singapore) | FCC (America), IC (Canada), RCM (Australia), Anatel (Brazil), Teleck MIC (Japan), KCC (South Korea) |

Power Requirements and Expected Battery Life

Power Requirements

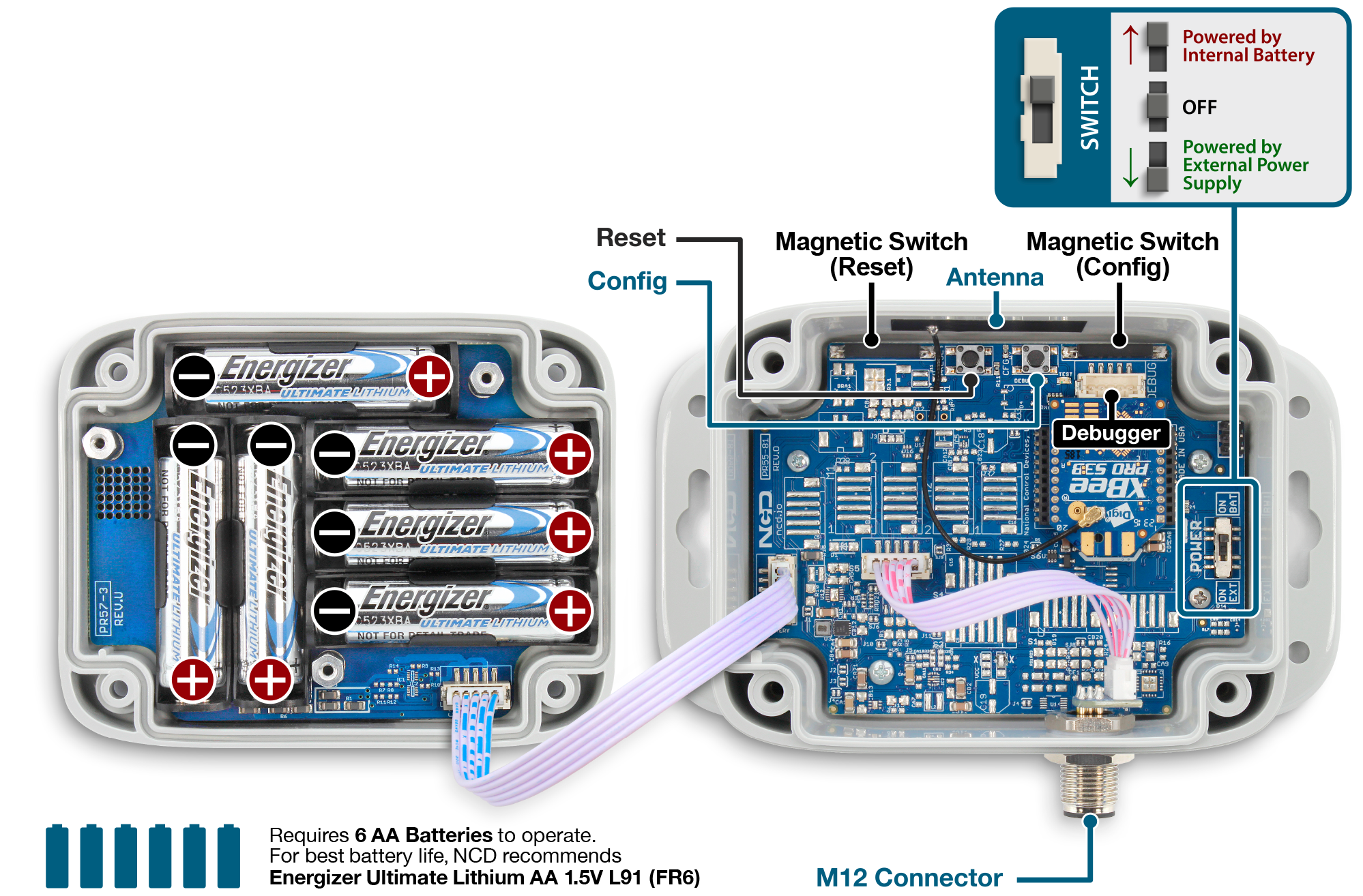

This Sensor has two power options:

- Powered by AA batteries (NCD recommends Energizer L91 batteries)

- External power supply (5-12 V DC) Current Requirement 250 mA (optional)

While changing the batteries:

- Turn off the sensor

- Only use new L91 batteries

- Checkout the polarity marking on the battery holder and batteries

- Replace all six batteries with new L91 batteries. Do not mix old and new batteries

- Batteries should not be replaced in fire-risky areas

- Do NOT install rechargeable batteries

Expected Battery Life

| Specifications | Minimum | Nominal | Maximum | Notes |

|---|---|---|---|---|

| Batteries | 2 | 6 | 6 | May be Powered by 2 or 6 AA Batteries |

| Battery Life 1 TPD (TPD Transmissions per Day) | 10 Years | Battery estimation is based on a 30 min interval | ||

| Battery Life 12 TPD (TPD Transmissions per Day) | 8 Years | Battery estimation is based on a 30 min interval | ||

| Battery Life 24 TPD (TPD Transmissions per Day) | 5 Year | Battery estimation is based on a 30 min interval | ||

| Battery Life 96 TPD (TPD Transmissions per Day) | 3 Year | Battery estimation is based on a 30 min interval |

Head to the NCD store if you want to purchase the C1D2 Industrial IoT Wireless Structural Monitoring Sensor.

If you already have the device and would like more information into its basic and advanced operations check out the Quick Start Guide and User Manual.