- Introduction

- Why Vibration? The Heartbeat of Your Machinery

- The Solution: Industrial IoT Sensors

- How to Start: Your 9-Step Implementation Plan

- Step 1: Asset Criticality & Classification (The Audit)

- Step 2: Select the Right Hardware

- Step 3: Prioritize Data Freedom and Open Integration

- Step 4: Evaluate how often you want to Monitor Vibration

- Step 5: Strategic Installation & Mounting

- Step 6: Select Your Analysis Platform

- Step 7: Establishing a Baseline

- Step 8: Data Interpretation & Root Cause Analysis

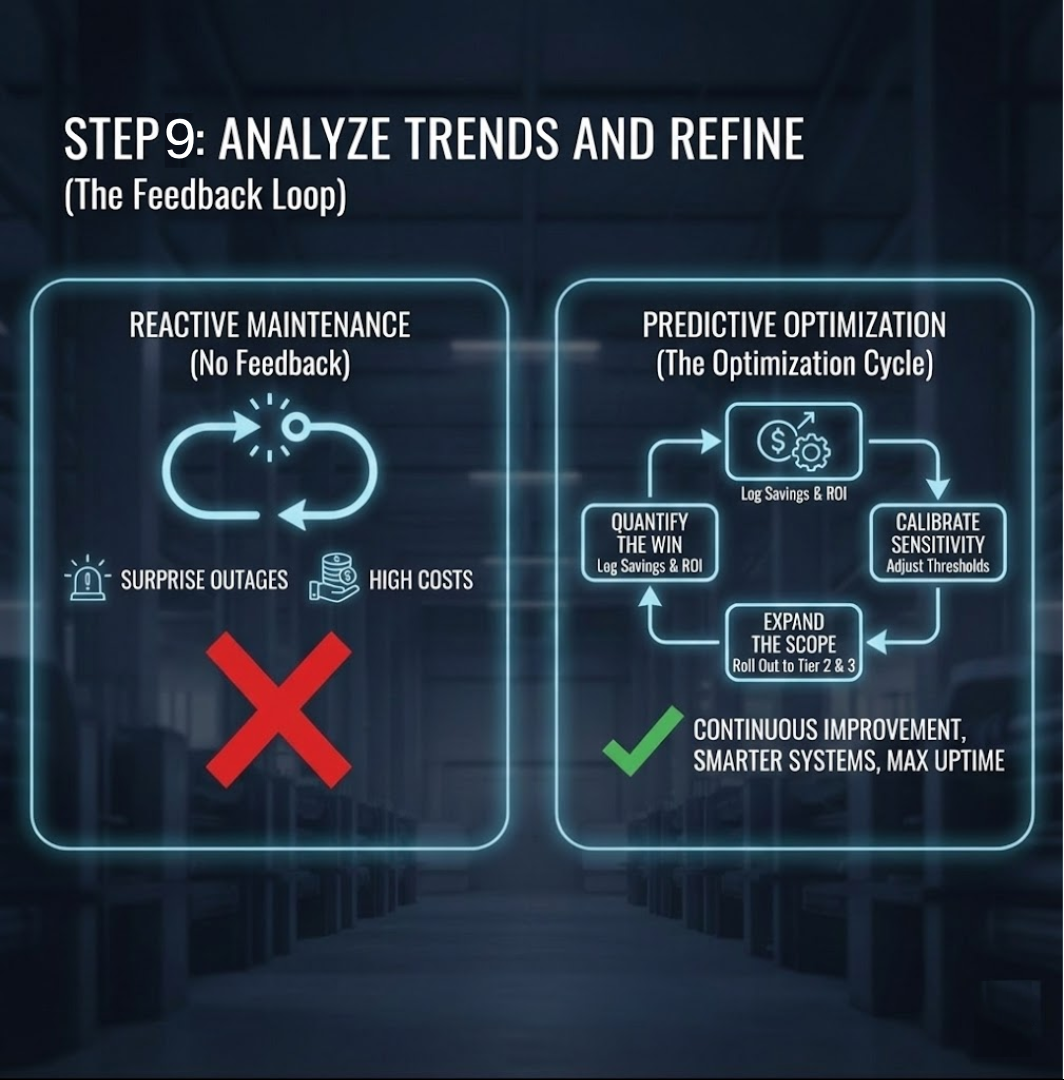

- Step 9: Analyze Trends and Refine

- Why the NCD is the Industry Standard

- Conclusion

- Connect

Introduction

Whether you are maintaining a single critical electric motor or managing thousands of assets across a sprawling industrial complex, the reality is the same: equipment failure is expensive. It halts production, forces overtime, and eats into profit margins.

But what if your machines could “talk” to you? What if they could tell you they were sick weeks before they actually broke down?

This is the promise of Predictive Maintenance (PdM) using Vibration Analysis. In this guide, we will break down the fundamentals of this technology, how it has evolved from manual checks to smart IoT solutions, and exactly what you need to know to start implementing it in your facility today.

The Evolution of Maintenance

To understand where we are going, we have to look at where we’ve been. Historically, maintenance strategies have fallen into two buckets:

1. Reactive Maintenance (Run-to-Failure)

Reactive maintenance, also called corrective maintenance or run-to-failure, is a strategy where equipment is repaired only after it breaks down or shows obvious signs of failure, rather than being serviced proactively. It’s a simple “if it ain’t broke, don’t fix it” approach, taking action only when a problem occurs to restore the asset to working condition, which can lead to unexpected downtime, higher costs, and shorter equipment life for critical assets

- The Downside: Unplanned downtime is catastrophic. Emergency repairs cost significantly more than planned maintenance, and parts may not be available.

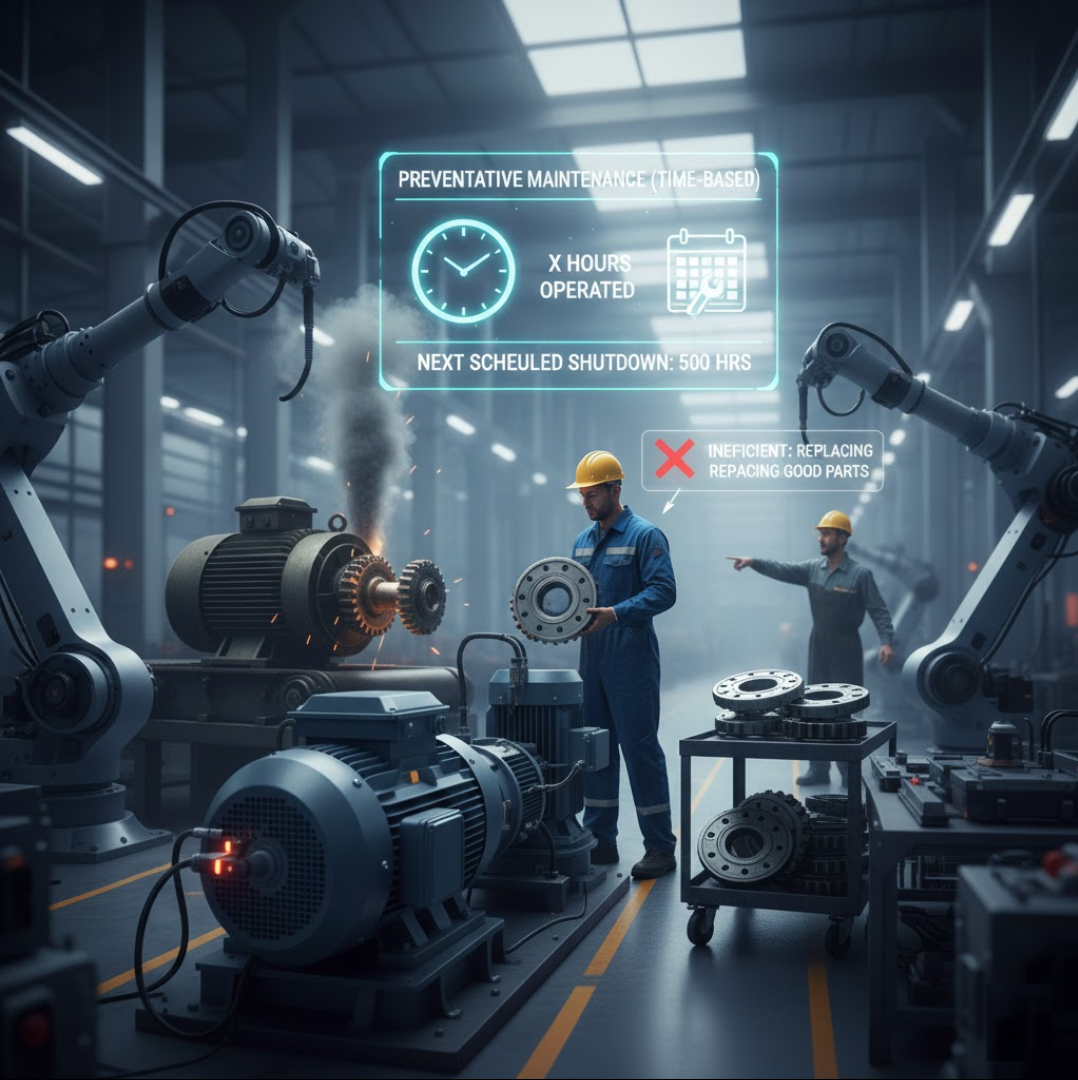

2. Preventative Maintenance (Time-Based)

This was the industry standard for decades, Preventative Maintenance is a strategy where equipment is serviced, inspected, or parts replaced at fixed, predetermined intervals (like monthly, quarterly, or yearly) on a calendar schedule, regardless of the asset’s actual condition, aiming to prevent failures, ensure reliability, and extend asset life by assuming wear increases with time. It’s simple to schedule, often based on manufacturer specs or regulations, but risks over-maintenance if usage varies greatly

- The Downside: It is inefficient. You often replace perfectly good parts “just in case,” or worse, a machine fails before its scheduled check-up.

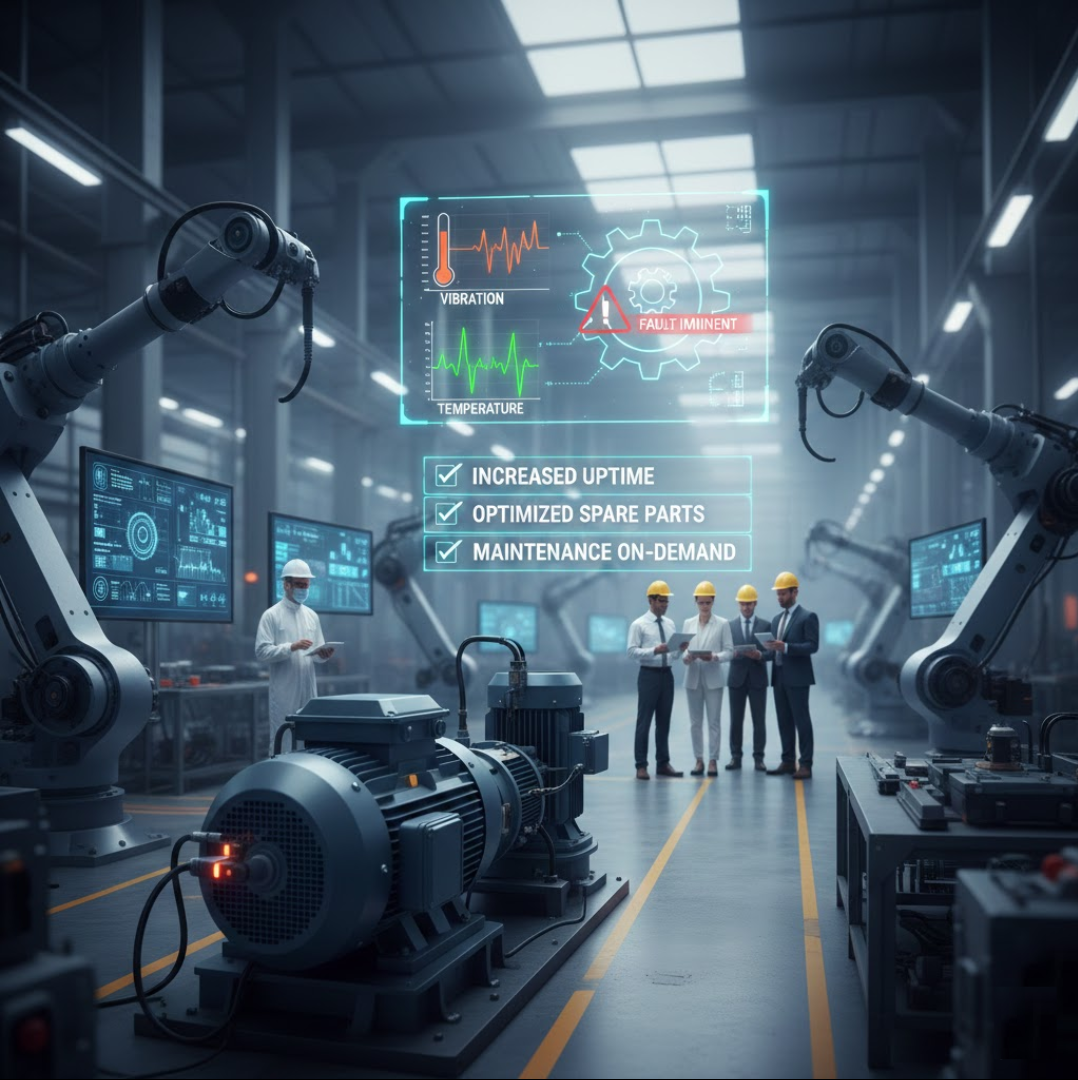

The Future: Predictive Maintenance (Condition-Based)

This is the Industry 4.0 standard. Instead of guessing, we use data. Predictive Maintenance (PdM), especially when referred to as Condition-Based Maintenance (CbM), is a proactive strategy using sensors and data to monitor equipment health in real-time, triggering maintenance just when needed—before failure but after maximum component life is used—instead of on a fixed schedule, cutting downtime and costs by analyzing trends, vibration, temperature, etc., with advanced analytics predicting future failures for optimal scheduling

- The ROI: Increased uptime, optimized spare parts inventory, and maintenance performed only when necessary.

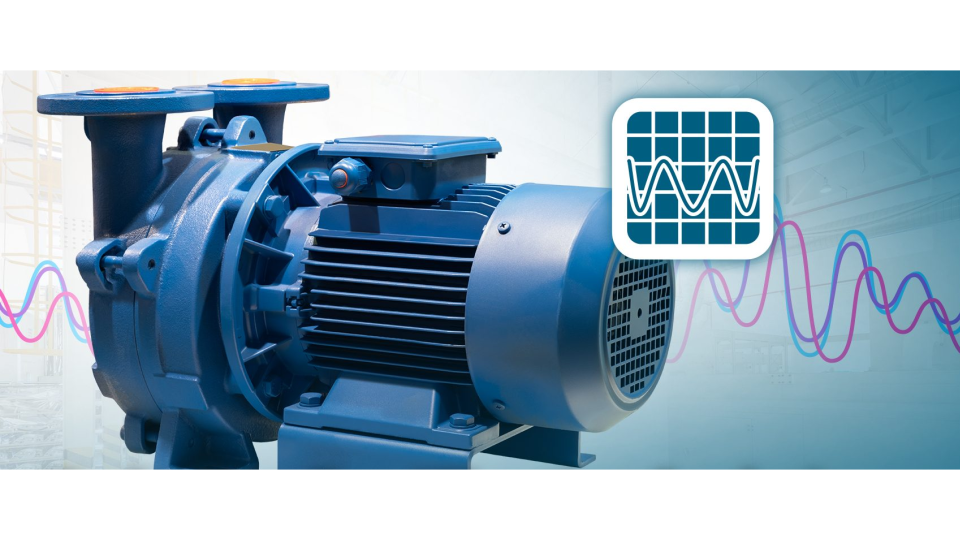

Why Vibration? The Heartbeat of Your Machinery

If temperature is the “fever” of a machine, vibration is its “heartbeat”. Every rotating asset—pumps, motors, fans, compressors—has a unique vibration signature. When components begin to degrade, that signature changes long before the machine gets hot or makes a noise audible to the human ear.

Vibration Analysis can detect:

- Bearing Wear: The most common failure mode.

- Misalignment: When shafts aren’t centered.

- Imbalance: Often caused by dirt build-up on fans or impellers.

- Looseness: Bolts rattling loose over time.

In essence, vibration analysis serves as a conversion process: it takes the physical motion of a machine, converts it into fundamental sensor data, and then distills that into practical, meaningful intelligence. This transition facilitates maintenance decisions that are more intelligent, quicker, and ultimately more effective, thus prolonging asset longevity and significantly cutting unexpected production stoppages. By analyzing changes in Frequency (what is vibrating) and Amplitude (how hard it is vibrating), we can pinpoint exactly what is failing and how bad it is.

The Importance of Vibration Analysis

Vibration analysis acts as a premier diagnostic tool for predicting breakdowns in industrial machinery. Unlike traditional methods that rely on human observation or waiting for a drop in performance, vibration monitoring delivers hard, data-driven insights into the internal state of an asset long before physical symptoms manifest. Detecting irregularities at their inception empowers maintenance engineers to pinpoint root causes and schedule repairs during standard maintenance windows. This proactive stance mitigates the danger of critical failures, prolongs asset longevity, boosts overall facility reliability, and significantly cuts operational costs by eliminating unplanned interruptions.

Common Application for Vibration Analysis

Vibration monitoring is a versatile tool utilized extensively across a broad spectrum of industrial sectors. Some of the most frequent use cases include:

- Pumps and Compressors: Essential assets in Oil & Gas, chemical processing, and wastewater treatment facilities. Vibration data is crucial here for detecting cavitation, early-stage bearing degradation, and flow-induced imbalance.

- Electric Motors: The workhorses of modern industry. Whether driving belts or direct loads, motors are susceptible to rotor eccentricity, shaft misalignment, and various electrical anomalies that vibration analysis can easily identify.

- Fans and Blowers: Ubiquitous in HVAC and air handling systems. These units frequently suffer from particulate buildup causing imbalance, structural looseness, or fan blade deformation.

- Gearboxes and Power Transmission: These complex mechanical systems are prone to gear mesh faults, subtle wear patterns, and lubrication failures—issues that often remain silent until significant damage has occurred.

- Turbines and Generators: In the power generation and energy sectors, these are high-value, critical assets. Even the slightest deviation in vibration signatures can signal impending issues that could lead to massive financial losses.

- CNC and Precision Tooling: For high-precision manufacturing, vibration sensors are key to monitoring tool sharpness, spindle alignment, and structural rigidity, ensuring that product quality remains consistent

The Solution: Industrial IoT Sensors

In the past, vibration analysis required hiring an expensive Category III vibration analyst to walk around with a handheld data collector once a month. This provided a snapshot, not a movie.

Today, we use Wireless IIoT (Industrial Internet of Things) Sensors. These devices are permanently mounted to your assets, monitoring them 24/7/365.

Enter the "Edge" Computing Era

Modern sensors, such as the NCD Gen4 Wireless Vibration & Temperature Sensor, don’t just record data; they “think.” This is critical for scaling a predictive maintenance program.

The Gen4 sensors utilize a feature called Smart Mode. Instead of clogging your network by sending massive amounts of raw data every second, the sensor processes data locally (on the device).

- Learning: It wakes up, samples the vibration, and calculates key metrics like RMS (Root Mean Square) and Max Peak.

- Filtering: If the data is within normal limits, it goes back to sleep to save battery.

- Alerting: If the vibration exceeds your defined threshold, it immediately wakes up and transmits the data to the cloud/gateway.

This “Edge Computing” approach allows for battery lives of up to 5+ years while ensuring you never miss a critical event.

To accurately pinpoint the source of a machine failure, analysts must isolate and interpret the complex vibration signals captured by the sensors. This diagnostic process relies heavily on two primary analytical techniques: Time Domain Analysis and Frequency Domain Analysis (using the Fast Fourier Transform, or FFT) . Each technique provides a distinct lens through which to view the machine’s health:

- Time Domain Analysis: This is the most fundamental view, observing the raw vibration signal as it behaves chronologically. It’s excellent for detecting transient events, impacts, looseness, or sudden shock loads that may momentarily spike the overall vibration level.

- Frequency Domain Analysis (FFT): The FFT is a mathematical process that transforms the raw time signal into a spectrum based on frequency. This is the crucial step for diagnostics, as specific machine faults—like an imbalance, misalignment, or a bearing defect—each generate vibration energy at unique, identifiable frequencies (fault signatures).

Working in tandem, these powerful techniques enable early fault detection, empowering maintenance teams to make highly informed, proactive decisions. The NCD Vibration Sensor Gen 4 simplifies this analysis significantly:

- Internal Processing: The sensor is capable of performing the FFT calculation internally, allowing it to transmit pre-processed data that gives an immediate overview of the machine’s vibration status.

- Data Flexibility: For deeper, expert-level analysis, the sensor can also transmit the raw Time Domain Data either upon request or automatically when certain thresholds are breached.

This combination of on-sensor processing and raw data availability makes the NCD Gen 4 a highly versatile and appealing solution in the industrial market.

How to Start: Your 9-Step Implementation Plan

Implementing a vibration monitoring strategy is not just about sticking magnets on motors; it is about creating a data workflow that turns physical movement into business decisions. Based on successful industrial deployments, here is the proven 9-step roadmap to building your Predictive Maintenance (PdM) ecosystem.

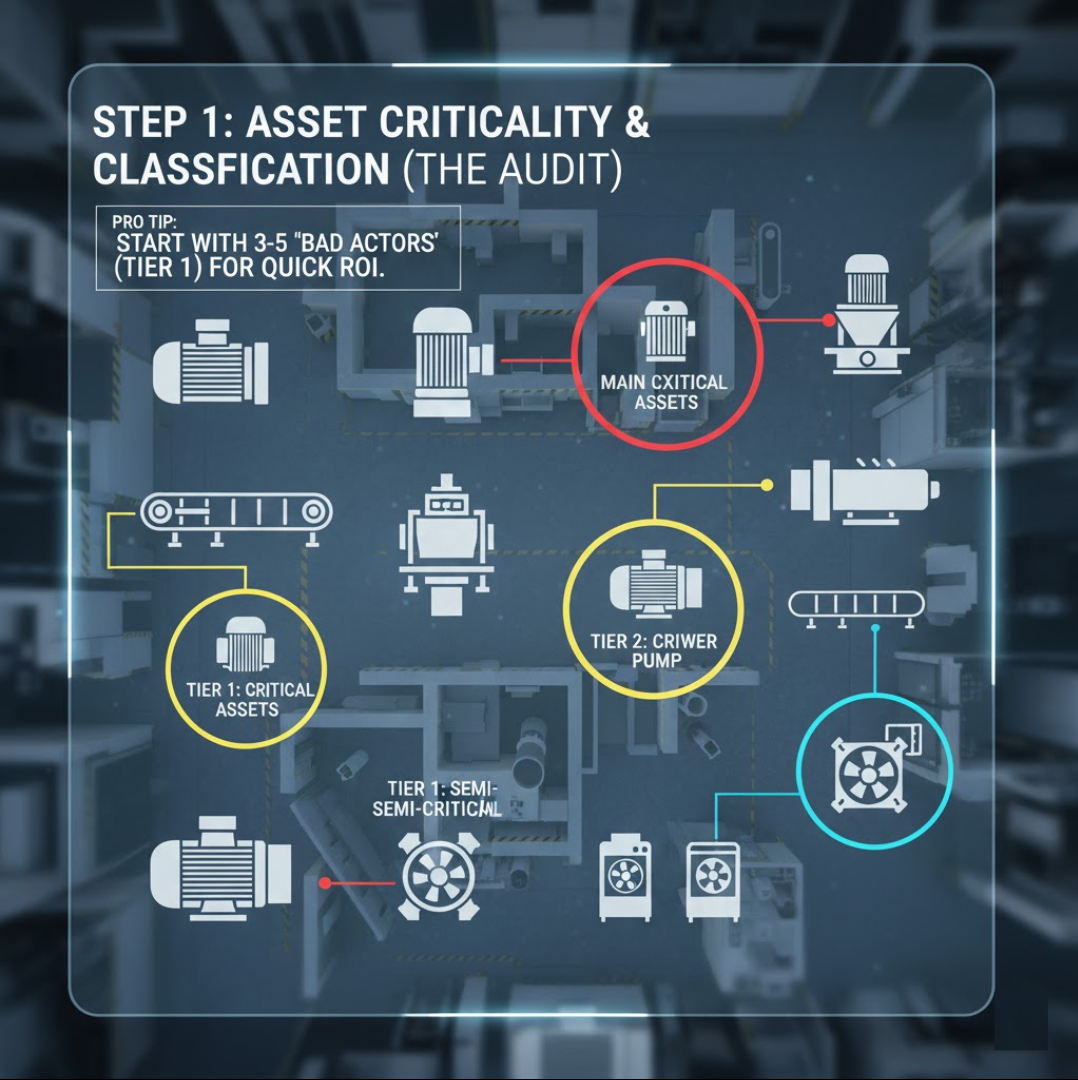

Step 1: Asset Criticality & Classification (The Audit)

You cannot monitor everything immediately. Start by auditing your facility and categorizing assets based on risk.

- Critical Assets (Tier 1): If these stop, production stops. (e.g., Main Extruders, Cooling Tower Pumps).

- Semi-Critical (Tier 2): If these fail, you have a backup or a buffer, but it strains the system.

- Balance of Plant (Tier 3): Exhaust fans or auxiliary pumps that are easily replaced.

- Pro Tip: For your first deployment, choose 3-5 “Bad Actors”—Tier 1 machines that have a history of unexpected failure. This provides the quickest ROI validation.

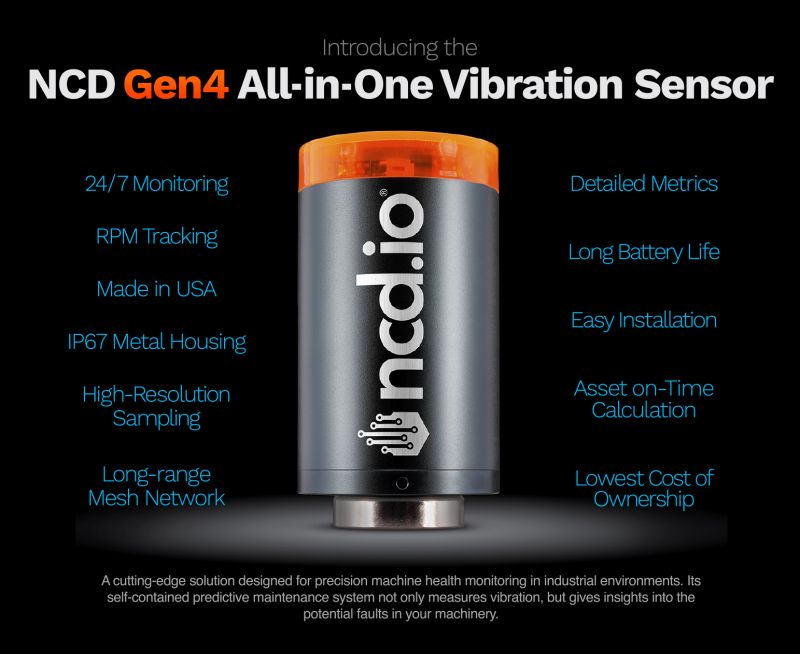

Step 2: Select the Right Hardware

Manual routes (technicians with handhelds) are prone to human error and safety risks. For a scalable modern solution, Wireless IIoT Sensors are the standard.

- Key Consideration: Ensure the sensor range matches your machine’s fault frequencies. A standard 5kHz bandwidth sensor (like the NCD Vibration Sensor Gen4) covers 90% of industrial faults (imbalance, misalignment, looseness, and late-stage bearing wear).

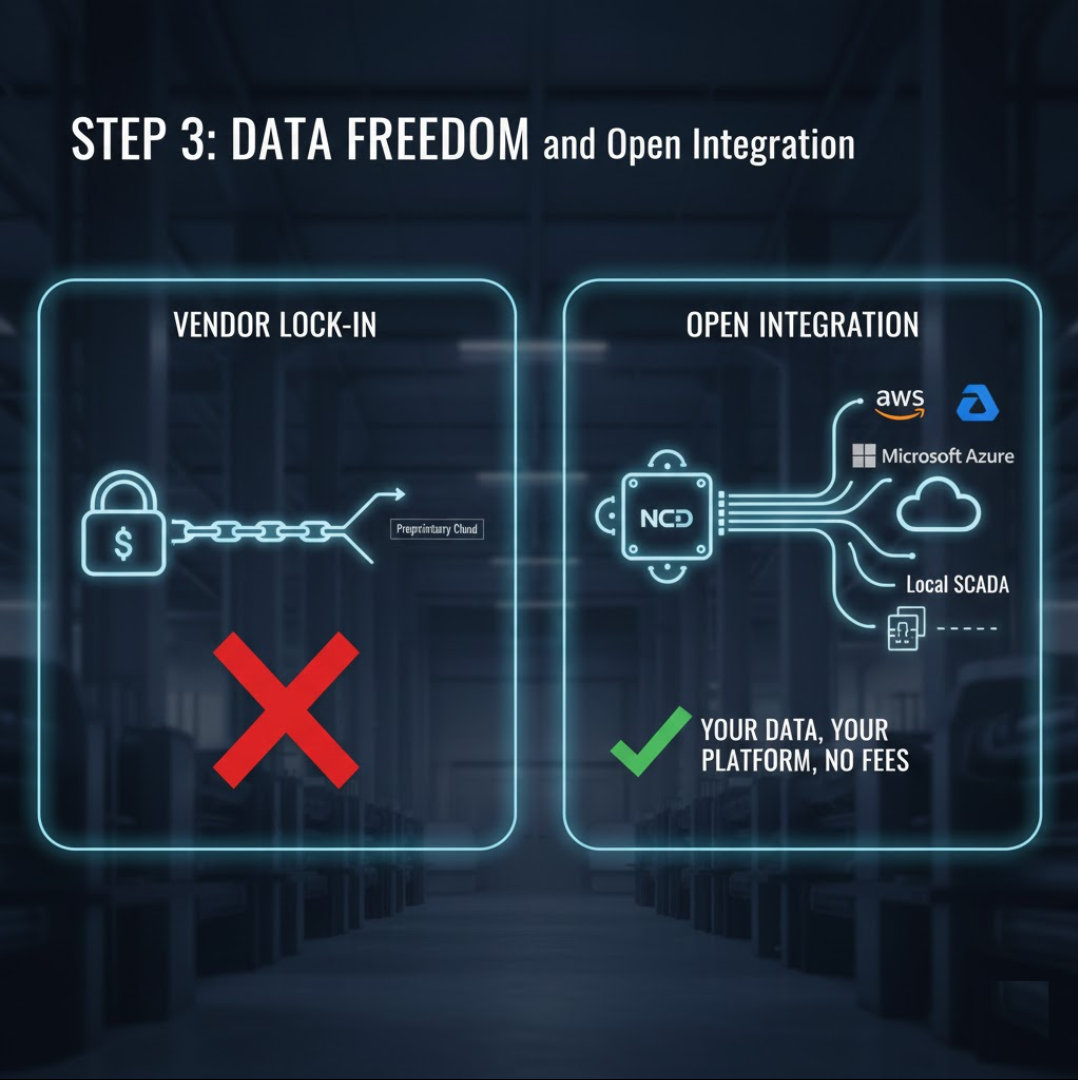

Step 3: Prioritize Data Freedom and Open Integration

(Avoid Vendor Lock-In)

This is a vital business decision often overlooked by technicians. Many IIoT solution providers offer “complete” packages (hardware + proprietary cloud software). While convenient initially, this approach frequently means giving the vendor total control over your data, analysis, and future costs.

Before committing, investigate the system’s integration flexibility:

- Open Protocol: Does the solution utilize open protocols (like MQTT or HTTP)?

- Freedom of Destination: Can you seamlessly direct the raw and processed data to your own platform, local SCADA, or preferred cloud service (AWS, Azure, Google Cloud)?

- Cost Model: Are there mandatory monthly subscription fees, per-sensor licensing, or annual charges just to access your own data?

The ideal solution provides the industrial-grade hardware and the freedom to use your own data, platform, and analytics tools, avoiding costly third-party contracts. This is the core principle of Data Freedom:

- From Device to You with No Contract: All collected sensor data is your personal property, giving you the freedom to manage it without monthly licensing traps or hidden fees. Solutions like the NCD Gen4 are designed to put the data control back into your hands.

Step 4: Evaluate how often you want to Monitor Vibration

One of the most common questions in predictive maintenance is: “How often should I measure?”

In the era of manual data collection, this was dictated by labor costs. sending a technician to check a motor every day was impossible, so plants settled for monthly or quarterly routes. The problem? Failures don’t stick to a calendar. A bearing can go from “initial wear” to “catastrophic seizure” in just a few weeks—completely unnoticed between monthly inspections.

The IoT Advantage: Catching the Failure Window With wireless IIoT sensors, you are no longer limited by human schedules. You can match the sampling interval to the criticality of the machine. This is about managing the P-F Interval: the time between when a potential fault is detectable and when the machine actually fails.

- High-Speed Assets (Critical): Motors or pumps running at high RPMs can degrade quickly. Monitoring these once every hour ensures you catch rapid changes in vibration before they cause damage.

- Standard Assets (Balance of Plant): For standard fans or conveyors, a check every 4 to 12 hours is often sufficient to track long-term trends like misalignment or looseness.

- The “Wake-on-Event” Factor: NCD Gen4 sensors add a layer of intelligence here. You can set a “heartbeat” check for every 4 hours to save battery, but configure the sensor to wake up immediately if vibration levels spike beyond a safety threshold. This gives you the battery life of a low-frequency sensor with the safety net of real-time monitoring.

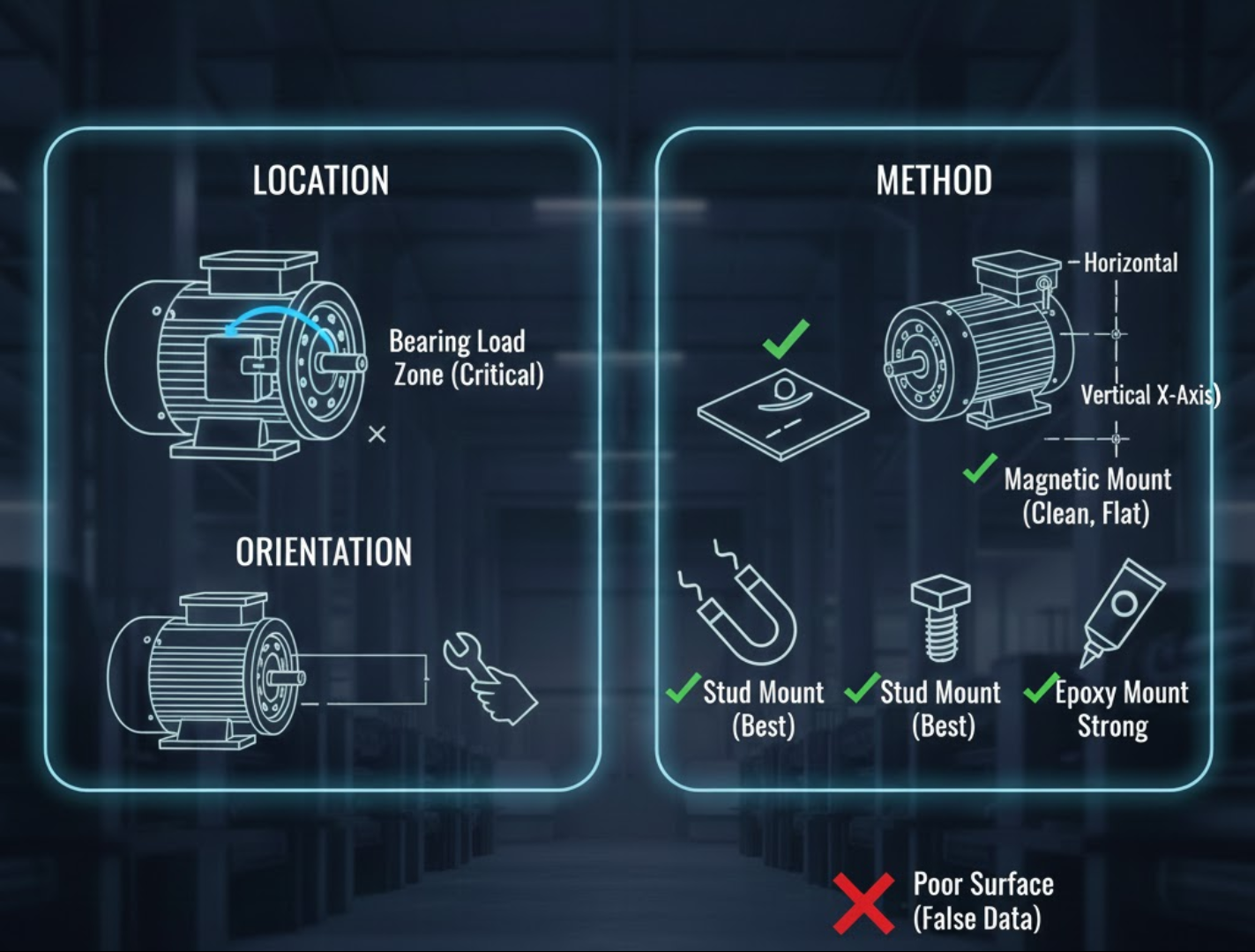

Step 5: Strategic Installation & Mounting

This is the most critical step. A vibration sensor is only as good as its mechanical connection to the machine. Poor mounting leads to dampened signals and false data.

- Location: Mount the sensor as close to the bearing load zone as possible.

- Orientation: Ensure you are measuring the correct axis. For radial bearings, you typically want horizontal and vertical readings.

- Method: While magnetic mounts are convenient for easy setup, ensure the surface is clean, flat, and free of thick paint. For the highest frequency response, stud mounting or industrial epoxy is recommended.

Reference: Getting this wrong invalidates your data. Review our Sensor Installation Best Practices before you begin.

Step 6: Select Your Analysis Platform

(Remember your sensor, your data)

Once your sensors are mounted and transmitting, that raw data needs a home. This is where your Analysis Platform comes in. It is the “brain” of your operation—the software where data is visualized, trends are tracked, and alerts are managed.

Because NCD sensors are built on an open architecture, you are not forced into a proprietary dashboard. You have the freedom to choose a platform that fits your specific needs, whether it’s a simple local gateway or a complex cloud infrastructure.

- Historical Database: Predictive maintenance relies on history. Your platform must be able to store years of data, allowing you to compare today’s vibration signature against the baseline you recorded six months ago.

- Local vs. Cloud: * Cloud (AWS, Azure, Losant): Best for remote access, heavy computation, and managing multiple sites.

- Local (Node-RED, Local SCADA): Best for high-security environments where data cannot leave the factory floor.

The NCD Advantage: Because “Your Sensor means Your Data,” you can start with a simple dashboard today and migrate to a powerful enterprise cloud solution tomorrow without changing a single sensor.

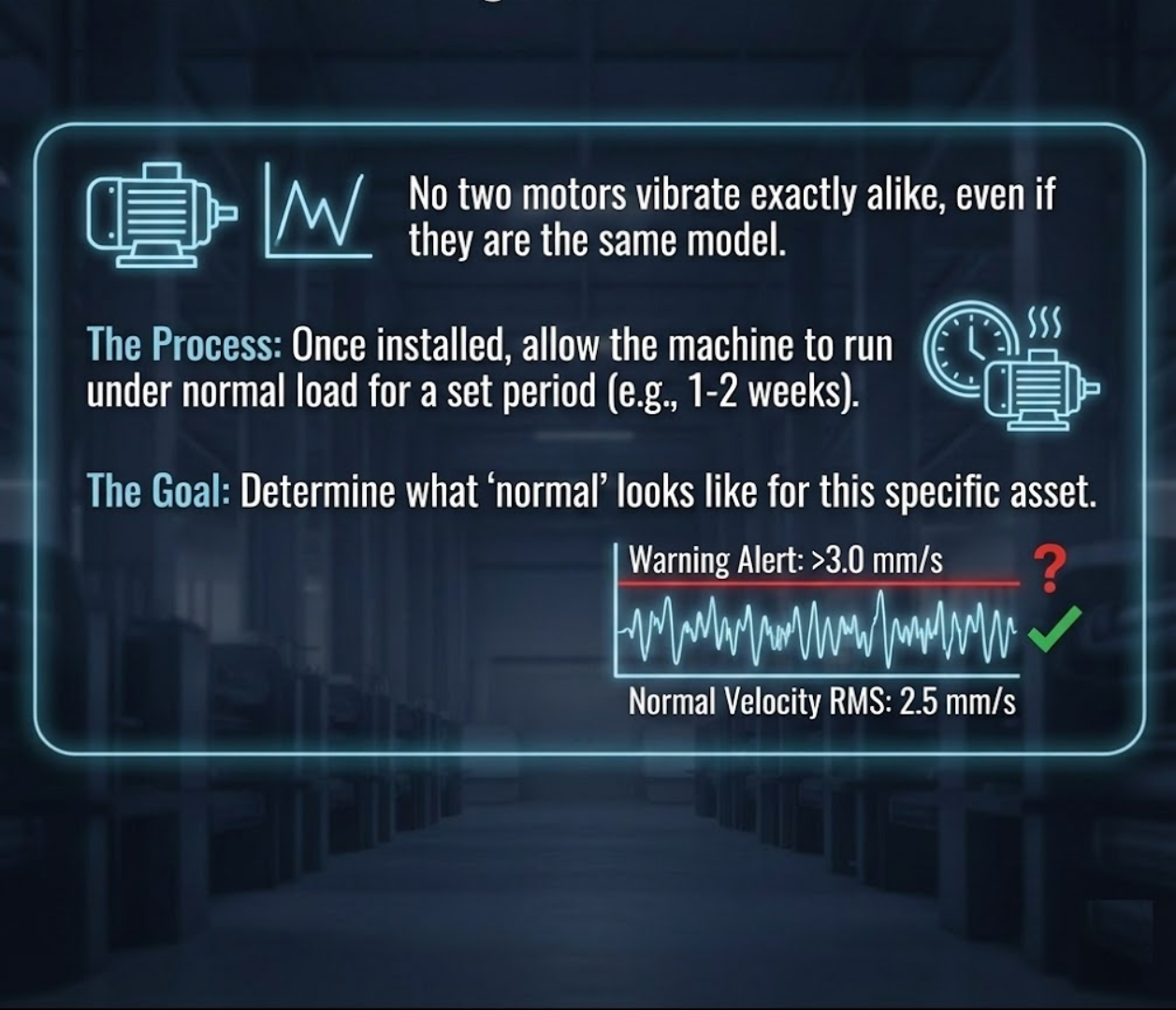

Step 7: Establishing a Baseline

No two motors vibrate exactly alike, even if they are the same model.

The Process: Once installed, allow the machine to run under normal load for a set period (e.g., 1-2 weeks).

The Goal: Determine what “normal” looks like for this specific asset. Does it naturally run at 2.5 mm/s Velocity RMS? If so, your warning alert shouldn’t be set at 3.0 mm/s.

NCD Advantage: Our advanced algorithms can help automate this baselining process, learning the machine’s behavior over time to reduce false alarms.

Step 8: Data Interpretation & Root Cause Analysis

Once the data is flowing, you move from “Data Collector” to “Analyst.”

- Level 1 (General Health): Watch the Velocity RMS trends. A gradual increase over weeks indicates wear; a sudden spike indicates a fracture or impact.

- Level 2 (Diagnostics): When a sensor flags a “Critical” status, initiate a High-Fidelity Data Request.

- Use Time Domain (Waveform) to spot impacts or looseness.

- Use FFT (Fast Fourier Transform) to identify the specific frequency of the fault.

Step 9: Analyze Trends and Refine

As your sensors gather data, you aren’t just monitoring the present; you are building a digital history for every asset. This long-term trend data is the key to sharpening your predictive strategy, eliminating surprise outages, and maximizing machine availability.

The Optimization Cycle Predictive maintenance is an iterative process, not a one-time project. Every time your system flags an issue and you prevent a breakdown, you feed that intelligence back into the program to make it smarter:

- Quantify the Win: When you intercept a failure, log the victory. How many hours of production did you save compared to a reactive repair? Documenting these “saves” provides the undeniable financial proof needed to justify the program’s value to leadership.

- Calibrate Sensitivity: Learn from every alert. If a warning triggered too late to be helpful, tighten your limits. If you received a false alarm, relax the threshold slightly. This constant tuning ensures your system evolves to become more precise with every rotation.

- Expand the Scope: Leverage the success of your initial pilot on critical “Bad Actors” to drive expansion. Use the proven ROI to justify rolling out sensors to your Tier 2 and Tier 3 assets, eventually blanketing the entire facility in protection.

Why the NCD is the Industry Standard

We designed the Gen4 Wireless Vibration & Temperature Sensor specifically to bridge the gap between complex vibration analysis and easy-to-use IoT.

- Complete Visibility: Fuses 3-Axis MEMS accelerometers with a precision surface temperature sensor.

- No Hidden Costs: We believe your data belongs to you. No monthly subscriptions, no licensing traps.

- Open Architecture: Whether you use AWS, Azure, Node-RED, or a custom SCADA, our sensors speak your language.

- Smart & Efficient: Configurable Smart Mode ensures you get the data you need without draining the battery or flooding your bandwidth.

The NCD Gen4 Roadmap: From Installation to Insight

To successfully implement predictive maintenance with the NCD Gen4 Vibration Sensor, follow this streamlined four-phase process:

Step 1 – Deployment & Data Collection: Securely mount the sensor to your asset’s bearing housing. Allow the sensor to monitor the equipment under normal operating conditions for 1–2 weeks to capture a complete picture of its “healthy” state.

Step 2 – Establishing a Baseline: Compare your collected data against the manufacturer’s vibration specifications. If those are unavailable, use the average readings from your initial collection period to establish a custom baseline, assuming the machine is in known good condition.

Step 3 – Automated Monitoring: Set your warning and critical thresholds based on this baseline. The Gen4 sensor will now monitor the asset 24/7, only transmitting alerts when it detects an anomaly that exceeds your set limits (Smart Mode).

Step 4 – Diagnostic Deep-Dive: If an alert is triggered, use the NCD library to request Time Domain data. Perform an FFT analysis to identify the root cause—such as bearing wear or misalignment—before a failure occurs.

Conclusion

Predictive maintenance is no longer a luxury for high-end manufacturers; it is a necessity for anyone who wants to remain competitive. By listening to the vibrations of your machines, you can stop fighting fires and start managing your plant proactively.

Ready to start your Predictive Maintenance journey? Explore the NCD Industrial IoT Vibration Sensors and see how easy it is to digitize your maintenance strategy today.

Connect

Seeking next-generation IIoT Smart Vibration Sensors and support? Here are some next steps:

- Cuntact us to talk to a NCD Technicial Support.

- Visit our Blog Entries to learn about emerging trends.

- Shop for solutions from NCD and our partners.